Press release

Intertronics brings UV post-cure to 3D SLA polymer printing technology

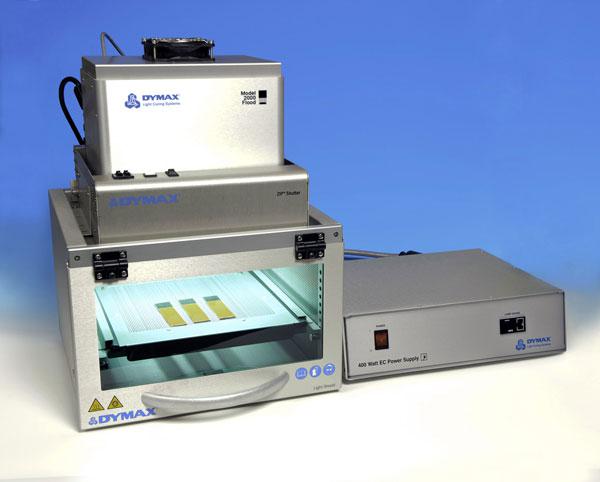

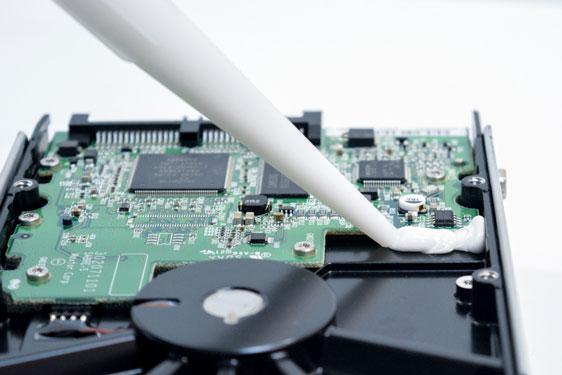

Recent developments in 3D printing technology have popularised the SLA (stereolithography) technology of laser printing in a bath of UV curable photopolymer resin. This process effectively “grows” a component in the bath so that as it is withdrawn, each successive layer is laser light cured. It is a process which can be many times faster than other 3D technologies, but does frequently need additional post-curing to ensure the component attains full strength and that any excess polymer that does not drain away in the build or growth process is completed cured.The DYMAX UV flood lamp and spot curing systems from Intertronics are ideal both for this post-curing application, and also for subsequent re-working and repair.

Intertronics explain that Dymax UV light-curing flood-lamp systems are designed for area curing or for curing multiple assemblies at once. These flood-lamp models use a powerful UV light-curing lamp (up to 225 mW/cm2) for fast curing over a 13 cm x 13 cm area. For rework or repair, such as curing drain-hole fills, assembling larger assemblies, or repairing cracked or broken models, the company’s BlueWave® 200 3.0 spot-lamp system is an ideal solution. This unit is a high-intensity lamp that emits energy in the UVA and visible portion of the spectrum (300-450 nm) and is well suited for either manual or automated processes. It contains an integral shutter which can be actuated by a foot pedal or PLC and a universal power input that allows operation globally and provides consistent performance at any voltage.

DYMAX UV flood and spot lamps may be used as bench-top curing systems or integrated into automated production lines where they provide the industry’s most consistent light intensity over their 2000 hour bulb warranty.

For further information please see www.intertronics.co.uk/uv-curing or visit the Intertronics blog at www.adhere.uk.com

"adhere” from INTERTRONICS - dedicated to providing quality adhesive solutions to high technology, high performance assembly industries, incorporating outstanding levels of technical support and customer service.

The adhere concept covers our range of adhesives, encapsulants, coatings, sealants and tapes as well as the associated dispensing, curing and surface preparation equipment and materials used in the manufacturing and assembly processes. Also our Opti-tec brand of adhesives.

Intertronics have been certified to ISO 9001:2008 standard demonstrating their commitment to customer service and quality in delivery. Certification proves that the Intertronics quality management system ensures consistency and a continuous improvement ethic, leading to high levels of performance and customer satisfaction.

Sales partners include: Araldite, Thinky, Fisnar, DYMAX, Plato, Practical Components, Sipel, Techspray, 3DT Corona Treating Systems, SolderQuick, preeflow, Polytec PT, Opti-tec, Circuit Medic and ACC Silicones.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

blog: www.adhere.uk.com

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Intertronics brings UV post-cure to 3D SLA polymer printing technology here

News-ID: 334726 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for DYMAX

Epoxies Market Development 2019 - Ashland, 3M, Dymax, Adhesive Systems

Epoxies Market Research Report Formulates with historic data up to 2019 and gives a forecast for 2019-2024. The report gives a comprehensive outlook of the market including the current market status, historic, and expected way forward for the global Epoxies market. The report inspects market size, key trends, technologies, challenges, product scope, industry revenue, and growth opportunities. The report delivers data on the drivers and restraints positively and adversely impacting…

Industrial Spray Valves Market 2017 - Dymax, Nordson, Fisnar, SchuF Group

Apex Market Researchs, recently published a detailed market research study focused on the "Industrial Spray Valves Market" across the global, regional and country level. The report provides 360° analysis of "Industrial Spray Valves Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Industrial Spray Valves industry, and estimates the future trend of…

Global UV Curing System Market 2017 : Phoseon, Nordson, CureUV.com, Dymax, Excel …

Market Research Explore, shares detailed market research study concentrates on the "UV Curing System Market" across the globe. The report provides comprehensive analysis of "UV Curing System Market" in the sense of manufacturers, regions, product segments and end industries. The research report analyses and provides the factual data along with current achievements of the global UV Curing System industry, and estimates the long run trend of UV Curing System market…

Polyether Acrylate Market 2017 - BASF, Huntsman, Dymax Corporation, Solvay, EVER …

Apex Research, recently published a detailed market research study focused on the "Polyether Acrylate Market" across the global, regional and country level. The report provides 360° analysis of "Polyether Acrylate Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Polyether Acrylate industry, and estimates the future trend of Polyether Acrylate market…

Global Engineering Adhesives Market 2017 - Sika, UNISEAL, Huntsman, Permabond, D …

Focuses on top manufacturers in global market, with Production, price, revenue and market share for each manufacturer

The report firstly introduced the Engineering Adhesives basics: definitions, classifications, applications and industry chain overview; industry policies and plans; product specifications; manufacturing processes; cost structures and so on. Then it analyzed the world's main region market conditions, including the product price, profit, capacity, production, capacity utilization, supply, demand and industry growth rate etc. In…

Global Glass Bonding Adhesives Market: Key Vendors - Dymax, KIWO, Permabond

Latest industry research report on: Global Glass Bonding Adhesives Market : Industry Size, Share, Research, Reviews, Analysis, Strategies, Demand, Growth, Segmentation, Parameters, Forecasts

Download Sample copy of this Report at :http://www.marketresearchreports.biz/sample/sample/1068179

Glass bonding adhesives are used for bonding glass to metal or glass to glass in numerous substrates. The most commonly used glass bonding adhesives are UV/LED curing systems, cyanoacrylates, epoxies, polyurethanes, and silicones. The global glass bonding adhesives market is segmented…