Press release

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting chemistries and speeds assembly time

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.Elastosil N9111 is also well-suited for automotive and small appliance electronics and for new/sustainable energy devices and similar. Further applications for this general-purpose adhesive sealant include demanding bonding applications in the household appliances sector, e.g. bonding of ceramic hobs, screens and control panels in electric cookers, or mounting and bonding of front windows of microwave ovens.

This new adhesive sealant is technically an alkoxy-curing RTV-1 system, formulated with a tin-free catalyst. It is therefore ideal for applications in which organo-tin compounds act as inhibitors and are therefore undesirable, such as dam-and-fill applications.

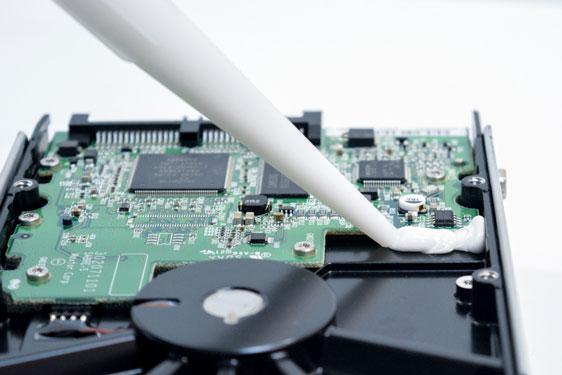

For instance, Elastosil N9111 makes encapsulation of electronic modules significantly quicker and easier in situations such as dam-and-fill. In this process, a bead of non-sag silicone is applied to the module to create a dam around the encapsulation area, which is then filled with a low viscosity encapsulant such as a platinum-catalysed silicone gel. This avoids the situation which occurs if the RTV-1 silicone used for the bead contains a tin catalyst, in which case the silicone must be fully cured before encapsulation - otherwise the tin will inhibit the curing of the platinum-catalysed encapsulant. As a result, using tin-based RTV-1 silicones for such procedures is always time consuming and cost intensive. Elastosil N9111 has none of these drawbacks and consequently promotes productivity and process simplicity.

Physically, Elastosil N9111 is a soft, non-sag paste. Its viscosity decreases when shear is applied. This "shear-thinning" enables the silicone rubber compound to be readily applied both manually and mechanically. The material is available in black and white and adheres to many conventional substrates, such as aluminium, stainless steel, glass, polyamide and polyvinyl butyral. The cured rubber is resistant to both UV light and temperatures of up to 200 °C.

Elastosil N9111 therefore offers considerable time savings and processing advantages.

For further information please see www.intertronics.co.uk/product/silicone-adhesive-sealants or visit the Intertronics blog at www.intertronics.co.uk/blog.

Intertronics supplies adhesives, coatings, sealants and equipment to customers with high technology, high performance assembly applications. Their customers are manufacturers in industries such as electronics, medical devices, plastics, optical, automotive, energy, defence and aerospace.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting chemistries and speeds assembly time here

News-ID: 1186081 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

WACKER Signs Up Intertronics for Silicone Distribution

Munich based chemical company WACKER and Intertronics are pleased to announce the signing of a distribution contract under which Intertronics will sell WACKER’s range of RTV silicone encapsulants and potting compounds, adhesive sealants, and thermally conductive compounds to customers in the UK and Ireland.

Intertronics’ customers are involved in technology manufacturing in areas such as electronics, lighting, automotive, defence and aerospace. WACKER’s silicone rubber products are used as sealants and gaskets,…