Press release

preeflow precision dispensing system from Intertronics improves quality and reduces rejects of automobile parts

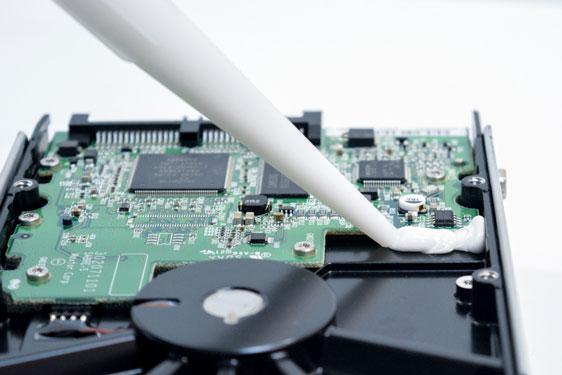

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable – the material dispense pressure - could not be monitored during application. The result was a high reject rate, and poor productivity due to process variability and the resultant need for heightened and laborious QA inspection.The preeflow team helped the customer to significantly improve the production process through implementation of more accurate dispensing technology. For process reliability, a two-part dispensing system from preeflow® is now used. The eco-DUO600 is a volumetric metering, mixing and dispensing unit which uses a progressive cavity pump principle to deliver precise amounts of the mixed sealant. The preeflow systems have precision control of the material output (which can be dynamically changed); this means that the FIP gasket application is very consistent along its entire dispensed path, including at the problematic area of the join.

The EC200-DUO controller includes material pressure monitoring and control. The preeflow eco-DUO system can be connected to the preeflow flowscreen monitoring unit, a device for showing the material process pressures on a graphic display.

Stable process for mass production is very important. With the help of the eco-DUO pressure sensors in combination with the flowscreen, the dispensing parameters can be displayed graphically in real time. Pressure fluctuations that can occur, for example, due to a blocked or defective dispensing needle, contamination, or cured material, are displayed in real time. This means that errors can be rectified immediately and the number of rejects can be minimised.

Peter Swanson, Managing Director of preeflow’s UK distributor, Intertronics, said: “Accuracy and repeatability are key concerns of our customers, and we frequently recommend preeflow dispensing systems in these types of scenarios. Whether our customers are dispensing a single-part or a two-part material, we have found preeflow systems provide a very high level of reliability combined with ease of use and real-time monitoring.” The preeflow eco-DUO system, which operates using the endless piston principle, along with the flowscreen pressure monitor, provide a repeatable and stable dispensing process. The system combines the benefits of reduced material costs with improved product quality.

For further information please see www.intertronics.co.uk/case-studies/ or visit the Intertronics blog at www.intertronics.co.uk/blog.

Intertronics supplies adhesives, coatings, sealants and equipment to customers with high technology, high performance assembly applications. Their customers are manufacturers in industries such as electronics, medical devices, plastics, optical, automotive, energy, defence and aerospace.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release preeflow precision dispensing system from Intertronics improves quality and reduces rejects of automobile parts here

News-ID: 1148448 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

WACKER Signs Up Intertronics for Silicone Distribution

Munich based chemical company WACKER and Intertronics are pleased to announce the signing of a distribution contract under which Intertronics will sell WACKER’s range of RTV silicone encapsulants and potting compounds, adhesive sealants, and thermally conductive compounds to customers in the UK and Ireland.

Intertronics’ customers are involved in technology manufacturing in areas such as electronics, lighting, automotive, defence and aerospace. WACKER’s silicone rubber products are used as sealants and gaskets,…

More Releases for Production

Fertilizer Catalyst Market to Undertake Strapping Growth During 2018 to 2028(Seg …

Global Fertilizer Catalyst Market Introduction

Rising demand for catalysts is being witnessed from the fertilizer industry. Fertilizer catalysts are various kinds of metal oxides which are used for increasing the reaction rate in the fertilizer industry. Fertilizer catalysts are primarily used during ammonia production. Fertilizer catalysts find applications in processes including methanol production, ammonia production, formaldehyde production, syngas production and others. The activity of the fertilizer catalyst decides the yield and…

Fertilizer Catalyst Market to Showcase Vigorous Demand during the Period until 2 …

Global Fertilizer Catalyst Market Introduction

Rising demand for catalysts is being witnessed from the fertilizer industry. Fertilizer catalysts are various kinds of metal oxides which are used for increasing the reaction rate in the fertilizer industry. Fertilizer catalysts are primarily used during ammonia production. Fertilizer catalysts find applications in processes including methanol production, ammonia production, formaldehyde production, syngas production and others. The activity of the fertilizer catalyst decides the yield and…

Polyethylene Market Macroeconomic Analysis Includes Product Capacity, Production …

Market Research Future Published a Half Cooked Research “Global Polyethylene Market Research Report – Forecast to 2027” – Market Analysis, Scope, Stake, Progress, Trends and Forecast up to 2027.

BASF SE, BP Plc, INEOS, Saudi Basic Industries Corporation, Petronas, China National Petroleum Corporation, China Petroleum & Chemicals Corporation, National Petroleum Company , Polimeri Europa ,Mitsui Chemicals Inc,Exxon Chemicals, Formosa Plastics Limited, Sumitomo Chemicals, DuPont, Chevron Philips,…

Collaborative Production Management Market : Production & Consumption Profession …

Global Collaborative Production Management Market: Snapshot

Collaborative production management products offer integrated solutions to the manufacturing systems, which helps in providing easy execution, real-time visibility, reporting, and tracking of the complete production processes. The use of collaborative production management solutions helps in reducing the cost of production through effective scheduling and management. In addition, the growing need of industries to ensure a high operational efficiency is estimated to accelerate the growth…

Semiconductor Production Equipment Market - Increasing Electronics Production Wo …

Global Semiconductor Production Equipment Market: Snapshot

Global market for semiconductor production equipment has been covered under the scope of this report. Semiconductor production equipment (SPE) is used in possibly the most advanced and complex manufacturing process in the world, which is, the production of semiconductor devices. Semiconductor products, such as memory devices and microprocessors are used in a wide range of devices such as personal computers, consumer electronics and telecommunications equipment.…

Vacuum Pumps Market Forecast by Production Value, Capacity and Production

Big Market Research Add New “Vacuum Pumps Market” Research Report to It’s a Database.

Request sample report @ https://goo.gl/cajJ1x

The report provides a basic overview of the Vacuum Pumps industry including definitions, classifications, applications and industry chain structure. And development policies and plans are discussed as well as manufacturing processes and cost structures.

This report studies Vacuum Pumps focuses on top manufacturers in global market, with capacity, production, price,…