Press release

Bending without limits – transfluid pipe bending machines

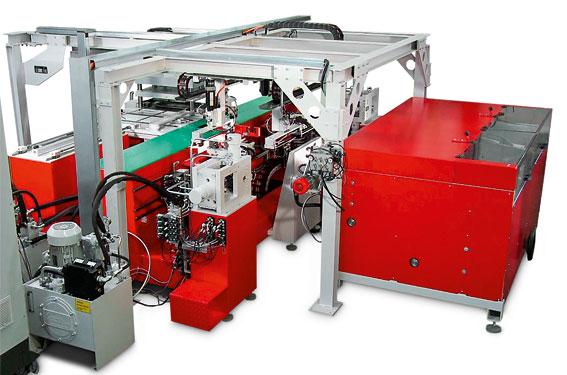

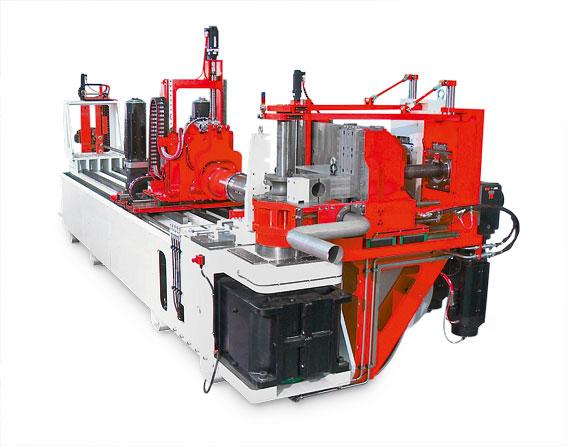

Specially designed tube bending machines t bend of transfluid® offers freedom for bendingSo specific the high requirements of industrial apipepplications are as individualized are the solutions of transfluid® in tube bending technology. The wide range offers advanced technology from compact mobile bending machines through powerful mandrel bending machines to impressive developments for bending pipes up to 300 mm diameter and 25 mm wall thickness.

For each application transfluid® provides manifold options - tube bending technology in semi-or fully automatic machines, with servo-electric and hydraulic drive, with bending direction right or left, as right + left bending machines, with push bending, equipped with handling systems or robots for fully automatic loading and unloading.

A powerful software solution for tube bending has created transfluid® with t control which also imports isometric data from all current CAD systems.

More information: http://www.tube-processing-machines.com/pipe-bending-machines.php

Contact:

transfluid®

Maschinenbau GmbH

Stefanie Flaeper

Hünegräben 20-22

57392 Schmallenberg

Germany

Tel.: +49 2972 97 15 - 0

Fax: +49 2972 97 15 - 11

info@transfluid.de

www.tube-processing-machines.com

transfluid® Maschinenbau GmbH – the solution for tubes

Since 1988 transfluid® continually improved technologies in tube processing to meet customers’ demands, offering optimum, tailor-made solutions in machine and plant construction, that are used in the automobile, ship building and furniture industries as well as the construction of railings and conveyor technology. The Schmallenberg-based company has become a global brand with service offices in Europe and Asia.

transfluid®’s product portfolio offers perfect solutions in five different machine categories, that meet all the requirements in tube processing. t bend includes semi- and fully-automatic tube bending machines as well as large-diameter tube bending machines.. t form represents high-quality axial, rolling and combined tube forming machines. Automation systems with sophisticated concepts for bending and forming technology belong to the t motion category. With t cut, transfluid® offers tube cutting machines in different system variants und t clean is transfluid®’s range of tube cleaning machines for guaranteed cleanliness of work pieces and pipes.

www.transfluid.de

www.tube-processing-machines.com

transfluid®

Maschinenbau GmbH

Stefanie Flaeper

Hünegräben 20-22

57392 Schmallenberg

Germany

Tel.: +49 2972 97 15 - 0

Fax: +49 2972 97 15 - 11

info@transfluid.de

www.tube-processing-machines.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Bending without limits – transfluid pipe bending machines here

News-ID: 178382 • Views: …

More Releases from transfluid® Maschinenbau GmbH

transfluid developed efficient manufacturing cell with three pipe bending machin …

Pipe bending: Sporting cycle time requirements successfully met

Pressure of competition and delivery reliability in the automotive sector also demand always new heights from the mechanical engineering. Optimal cycle times and automation systems that allow easy handling are crucial. Specialized in complex machinery solutions for tube processing is transfluid from Schmallenberg, Germany. For a renowned automotive supplier the german solution providers now developed an automated cell for the production of tubes…

The efficient simplicity of tube bending by transfluid

transfluid process for tube bending improves production performance

If special requirements are needed, sometimes less is more - also in order to optimize the output of high-quality results. In the area of the tube bending technology proves that the transfluid Maschinenbau GmbH with a solution that links the simple processes intelligently and effectively with each other. Because of customer request transfluid specialists now developed an economic system for the automatic…

Economical bending and cutting of compact geometries

New transfluid solution provides more time and material efficiency

In short and compact tube geometries, the problem is that with standard methods the material loss is extremely high, if must be cutted after bending the tubes. "Not acceptable", determine the developers of the transfluid Maschinenbau GmbH, Schmallenberg. With a special combination of bending and cutting process, which was developed according to the individual customer's request, provides the german company now an…

First process for tool-independent tube forming developed by transfluid

transfluid creates new technology for economic forming of individual geometries

In times of ever faster and more complex challenges to the production tool costs are one main cost factor. Nevertheless, it is common in tube forming that the form is mostly depending on the tooling. The only ways to take small influence on the geometry were until now changes in the material length and different strokes. With big efforts and…

More Releases for Fully

Fully automated Industrial Sputtering System| SELCOS

SELCOS Sputter Deposition System

SELCOS operates three methods in sputtering system. Those are Inline sputtering, Cluster sputtering and Batch sputtering system.

In the SELCOS Inline sputtering system, the process is fully automated to ensure stable quality and provides a wide range of expandability by its various applicable technologies. Its high mobility maximizesthe productivity. It is widely used for the various thin film processes such as metal, oxide and TCO. Also it…

Fully automatic deep hole drilling

TBT loading system allows unmanned shifts

Along with other precision machined components, GLUMANN Maschinenbau in Chemnitz, Germany specialises in producing long rotating shaft type parts. Deep Hole Drilling plays an important role the production of these items and so in order to keep up with the growing volume demands from an engineering customer, the contract manufacturer (GLUMANN) decided to equip their new Deep Hole Drilling Machine from TBT with a fully…

Fully Automatic External Defibrillator Market

https://www.qandqmarketresearch.com/reports/7228183/fully-automatic-external-defibrillator-market-79

The global Fully Automatic External Defibrillator market is valued at xx million US$ in 2017 and will reach xx million US$ by the end of 2025, growing at a CAGR of xx% during 20182025. The objectives of this study are to define, segment, and project the size of the Fully Automatic External Defibrillator market based on company, product type, end user and key regions.

This report studies the global market size…

Detectamet Fully Detectable Pen Refill

Refilling your Detectamet pen housing is cost effective, kinder on the environment and now safer than ever. Through significant innovation and development, Detectamet are proud to introduce the latest evolution in refills, further minimising the risk of foreign body contamination.

Fully detectable casing & tip

EU & FDA Compliant – Food contact safe.

Cost effective and kinder to the environment.

Blue & black standard inks available with red & green to follow.

Will replace…

Fully Automated Luminaire Testing Procedures

Delphin Test & Measurement Systems for Test Automation

Every day we depend on luminaire products for indoor lighting, whether at work or at home. As with all electro-technical devices, consumer safety is particularly important. Even the latest LED technology requires high-level testing for safety and reliability. For this reason, manufacturers put their newly-developed lamps through a multitude of tests before bringing them to market.

Especially important here are the thermal tests…

Fully automatic deep hole drilling

TBT loading system allows unmanned shifts

Along with other precision machined components, GLUMANN Maschinenbau in Chemnitz, Germany specialises in producing long rotating shaft type parts. Deep Hole Drilling plays an important role the production of these items and so in order to keep up with the growing volume demands from an engineering customer, the contract manufacturer (GLUMANN) decided to equip their new Deep Hole Drilling Ma-chine from TBT with a fully…