Press release

The efficient simplicity of tube bending by transfluid

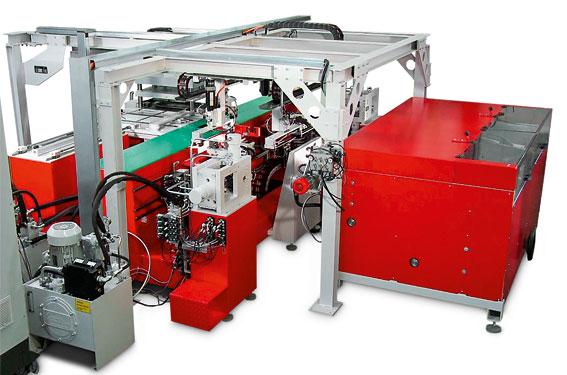

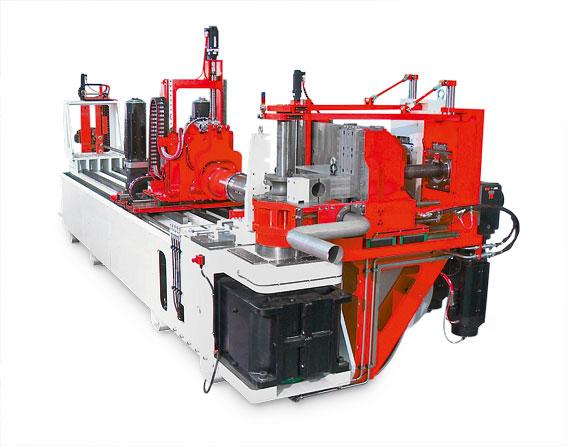

transfluid process for tube bending improves production performanceIf special requirements are needed, sometimes less is more - also in order to optimize the output of high-quality results. In the area of the tube bending technology proves that the transfluid Maschinenbau GmbH with a solution that links the simple processes intelligently and effectively with each other. Because of customer request transfluid specialists now developed an economic system for the automatic production of closed tube frames with up to six bends. The frame ends are reduced and merged during the bending process. The complete equipment solution includes an additional pressing device in which the fabricated tube frames are inserted automatically. "The challenge was to create an optimal process for our customer, which ensures efficient results fast and easy. And that with a cycle time of only 15 seconds”, explains Gerd Nöker, managing director of transfluid. At the establishment and development transfluid makes a point from the beginning that the entire system can be operated up to one hour without the deployment of personnel. For this purpose, the solution has a tube bunker that can accommodate 240 tubes with a diameter of 30 mm. After the separation process again the lenghts are measured and one tubeend is reduced automatically, so that both ends can be implemented into each other later. The tube bending process performs a transfluid double-head bending machine, which is equipped with two axially servo-electric positioned heads. "The two bending heads are always in use simultaneously, and the drive is also performed servo-electric ," explains Gerd Nöker. "The positioning of the workpiece in the tube bending process provides the automatic connection of the ends, creating a closed frame." Finally the automatic removal and feeding into the pressing device takes place. There various embossing punches fix the frame. By attaching different flattenings and punchings it is guaranteed, that during the later painting the paint can run smoothly.

During TUBE 2012 (26-30.03.2012, Düsseldorf, hall 05 / booth G34) visitors can experience more solutions for tube processing from transfluid.

transfluid Maschinenbau GmbH – the solution for tubes

Since 1988 transfluid continually improved technologies in tube processing to meet customers’ demands, offering optimum, tailor-made solutions in machine and plant construction, that are used in the automobile, ship building and furniture industries as well as the construction of railings and conveyor technology. The Schmallenberg-based company has become a global brand with service offices in Europe and Asia.

transfluid’s product portfolio offers perfect solutions in five different machine categories, that meet all the requirements in tube processing. t bend includes semi- and fully-automatic tube bending machines as well as large-diameter tube bending machines.. t form represents high-quality axial, rolling and combined tube forming machines. Automation systems with sophisticated concepts for bending and forming technology belong to the t motion category. With t cut, transfluid offers tube cutting machines in different system variants und t clean is transfluid’s range of tube cleaning machines for guaranteed cleanliness of work pieces and pipes.

www.tube-processing-machines.com

transfluid®

Maschinenbau GmbH

Stefanie Flaeper

Hünegräben 20-22

57392 Schmallenberg

Germany

Tel.: +49 2972 97 15 - 0

Fax: +49 2972 97 15 - 11

info@transfluid.de

www.tube-processing-machines.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The efficient simplicity of tube bending by transfluid here

News-ID: 211573 • Views: …

More Releases from transfluid® Maschinenbau GmbH

transfluid developed efficient manufacturing cell with three pipe bending machin …

Pipe bending: Sporting cycle time requirements successfully met

Pressure of competition and delivery reliability in the automotive sector also demand always new heights from the mechanical engineering. Optimal cycle times and automation systems that allow easy handling are crucial. Specialized in complex machinery solutions for tube processing is transfluid from Schmallenberg, Germany. For a renowned automotive supplier the german solution providers now developed an automated cell for the production of tubes…

Economical bending and cutting of compact geometries

New transfluid solution provides more time and material efficiency

In short and compact tube geometries, the problem is that with standard methods the material loss is extremely high, if must be cutted after bending the tubes. "Not acceptable", determine the developers of the transfluid Maschinenbau GmbH, Schmallenberg. With a special combination of bending and cutting process, which was developed according to the individual customer's request, provides the german company now an…

First process for tool-independent tube forming developed by transfluid

transfluid creates new technology for economic forming of individual geometries

In times of ever faster and more complex challenges to the production tool costs are one main cost factor. Nevertheless, it is common in tube forming that the form is mostly depending on the tooling. The only ways to take small influence on the geometry were until now changes in the material length and different strokes. With big efforts and…

From tube to isometry and vice versa: economical tube bending by transfluid

transfluid designs efficient solution for bending and processing of non-isometrized tubes

Object tubing is a frequent application in the shipbuilding industry in general and here especially in the hydraulics tubing. However, it is a fact that economic efficiency falls by the wayside if tubes are made-up at the object, manually drawn, bent on manual pipe bending machines and built in. Because after the tube bending process it is necessary to cut…

More Releases for Technology

Insurance Technology Market Outlook 2021 | TIA Technology, Patriot Technology So …

Insurance Technology Market has recently added by Qurate Research to its vast repository. This intelligence report includes investigations based on Current scenarios, Historical records, and future predictions. Report includes overview, which interprets value chain structure, industrial environment, regional analysis, applications, market size, and forecast. The report is integrated with imperative insights on the market, which will support the clients to make precise business decisions. The report incorporates data regarding the…

Global Insurance Technology Market 2019 – Top Companies Xchanging, Insurance T …

"Insurance Technology or Insurtech refers to the use of technology innovations designed to squeeze out savings and efficiency from the current insurance industry model. Insurtech is a portmanteau of “insurance” and “technology” that was inspired by the term fintech.”

Global Insurance Technology Market Research Report is a valuable source of insightful data for business strategists. Provides industry Overviews, including Growth Analysis, Past & Future Costs, Revenue, Demand and Supply Data (where…

Insurance Technology Market Analysis By Major Players | Xchanging, Insurance Tec …

The global Insurance Technology market size was million US$ and it is expected to reach million US$ by the end of 2025, with a CAGR of between 2018 and 2025.

This report studies the Insurance Technology market size by players, regions, product types and end industries, history data 2013-2017 and forecast data 2018-2025; This report also studies the global market competition landscape, market drivers and trends, opportunities and challenges, risks and…

Insurance Technology Market – Major Technology Giants in Buzz Again | TIA Tech …

Global Insurance Technology Market Size, Status and Forecast 2025 is latest research study released by HTF MI evaluating the market, highlighting opportunities, risk side analysis, and leveraged with strategic and tactical decision-making support. The study provides information on market trends and development, drivers, capacities, technologies, and on the changing capital structure of the Global Insurance Technology Market. Some of the key players profiled in the study are Xchanging, Insurance Technology…

Global Insurance Technology Market 2018-2025 Health and Life Insurance By Xchang …

In 2017, the global Insurance Technology market size was million US$ and it is expected to reach million US$ by the end of 2025, with a CAGR of between 2018 and 2025.

This report studies the Insurance Technology market size by players, regions, product types and end industries, history data 2013-2017 and forecast data 2018-2025; This report also studies the global market competition landscape, market drivers and trends, opportunities and challenges,…

Ultrasonic Technologies Market by Technology (Motor/actuator technology, medical …

The global ultrasonic technologies market provides alteration of processes with the use of oscillating sound of very high frequency. It is expected that the market would grow at a respectable rate as the technology is being widely adopted. Various verticals such as industrial units and healthcare are using ultrasound as it is considered a highly efficient technology. In the healthcare sector, it is used for diagnosis and treatment by minimal…