Press release

Detailed Information on the Complete Production Process of Wheel Weights

Wheel weights [https://www.fortunewheelparts.com/wheel-weights/] play a crucial role in the automotive industry, ensuring that vehicles maintain proper balance and stability. These small yet significant components are essential for the smooth operation of wheels [https://www.fortunewheelparts.com/wheel-accessories/], particularly in vehicles that require precise alignment and weight distribution. In this article, we will delve into the production process of wheel weights, exploring the materials used, manufacturing techniques, and quality control measures that ensure their effectiveness.Understanding Wheel Weights

Before we dive into the production process, it's important to understand what wheel weights are and why they are necessary. Wheel weights are small metal or plastic pieces attached to the rim of a wheel to balance it. When a wheel is not properly balanced, it can lead to uneven tire wear, vibrations, and decreased fuel efficiency. By adding wheel weights, mechanics can ensure that the weight is evenly distributed around the wheel, enhancing the vehicle's performance and safety.

Materials Used in Wheel Weight Production

The production of wheel weights involves various materials, each chosen for its specific properties. The most common materials include:

1. Lead [https://www.fortunewheelparts.com/lead/]: Traditionally, lead has been the material of choice for wheel weights due to its density and malleability. However, due to environmental concerns and regulations, the use of lead has been declining.

2. Zinc [https://www.fortunewheelparts.com/zinc/]: Zinc is becoming increasingly popular as a substitute for lead. It is less toxic and offers similar weight properties, making it an excellent alternative for wheel weights.

3. Steel [https://www.fortunewheelparts.com/steel/]: Steel wheel weights are also common, particularly for larger vehicles. They are durable and can withstand harsh conditions, although they may be heavier than their zinc or lead counterparts.

4. Plastic: Some wheel weights are made from plastic, particularly for lighter vehicles. These weights are often used in conjunction with adhesive backing for easy application.

Image: https://www.fortunewheelparts.com/uploads/M_007072.jpg

The Production Process of Wheel Weights

The production of wheel weights involves several key steps, from material selection to final quality checks. Here's a detailed look at each stage of the process:

Environmental Considerations

1. Material Selection

The first step in the production process is selecting the appropriate material. Manufacturers must consider factors such as weight, cost, environmental impact, and regulatory compliance. Once the material is chosen, it is sourced from suppliers and prepared for manufacturing.

2. Melting and Casting

For metal wheel weights, the next step is melting the selected material. This process typically occurs in a furnace where the metal is heated to its melting point. Once melted, the liquid metal is poured into molds to create the desired shape and size of the wheel weights. - Lead Casting: In the case of lead, the molten metal is poured into molds that are designed to create specific weight configurations. After cooling, the weights are removed from the molds. - Zinc and Steel Casting: Similar processes are used for zinc and steel, although the melting points and techniques may vary slightly due to the different properties of these metals.

3. Machining and Finishing

After casting, the wheel weights often require additional machining to achieve precise dimensions. This may involve cutting, grinding, or drilling to ensure that the weights fit perfectly on the wheel rims.Finishing processes, such as coating or painting, may also be applied to enhance the appearance and protect the weights from corrosion. For example, zinc weights may be coated with a layer of zinc to prevent rusting, while plastic weights may be colored for aesthetic purposes.

4. Quality Control

Quality control is a critical aspect of the production process. Manufacturers implement rigorous testing procedures to ensure that each wheel weight meets industry standards and specifications. This may include: - Weight Testing: Each weight is weighed to ensure it meets the specified tolerance levels. - Dimensional Inspection: Measurements are taken to confirm that the weights are within the required dimensions. - Durability Testing: Weights may be subjected to stress tests to evaluate their performance under various conditions.

5. Packaging and Distribution

Once the wheel weights have passed quality control, they are packaged for distribution. Packaging is designed to protect the weights during transportation and storage. Manufacturers often provide detailed labeling, including weight specifications and installation instructions, to assist mechanics and consumers.The final step involves shipping the packaged wheel weights to retailers, automotive shops, and manufacturers, where they will be used in vehicle assembly or maintenance.

Image: https://www.fortunewheelparts.com/uploads/IMG_7262.jpg

As the automotive industry becomes increasingly aware of environmental issues, the production of wheel weights has also evolved. The decline in lead usage is a direct response to environmental regulations aimed at reducing toxic materials. Manufacturers are now focusing on sustainable practices, such as recycling materials and minimizing waste during production.

Additionally, the shift towards lighter materials, such as plastic and zinc, reflects a broader trend in the automotive industry to improve fuel efficiency and reduce emissions. By using lighter wheel weights, vehicles can achieve better performance while also being more environmentally friendly. ConclusionThe production process of wheel weights is a complex and meticulous endeavor that plays a vital role in the automotive industry. From material selection to quality control, each step is designed to ensure that these small components effectively contribute to vehicle performance and safety. As the industry continues to evolve, manufacturers are adapting their processes to meet environmental standards and consumer demands, paving the way for a more sustainable future in automotive manufacturing. Understanding the intricacies of wheel weight production not only highlights the importance of these components but also underscores the ongoing innovations within the automotive sector. As technology advances, we can expect further improvements in the materials and methods used to produce wheel weights, ultimately enhancing the driving experience for consumers worldwide.

Media Contact

Company Name: Ningbo Fortune Auto Parts Manufacture Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=detailed-information-on-the-complete-production-process-of-wheel-weights]

Phone: 86-574-87277199

Country: China

Website: https://www.fortunewheelparts.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Detailed Information on the Complete Production Process of Wheel Weights here

News-ID: 3696802 • Views: …

More Releases from ABNewswire

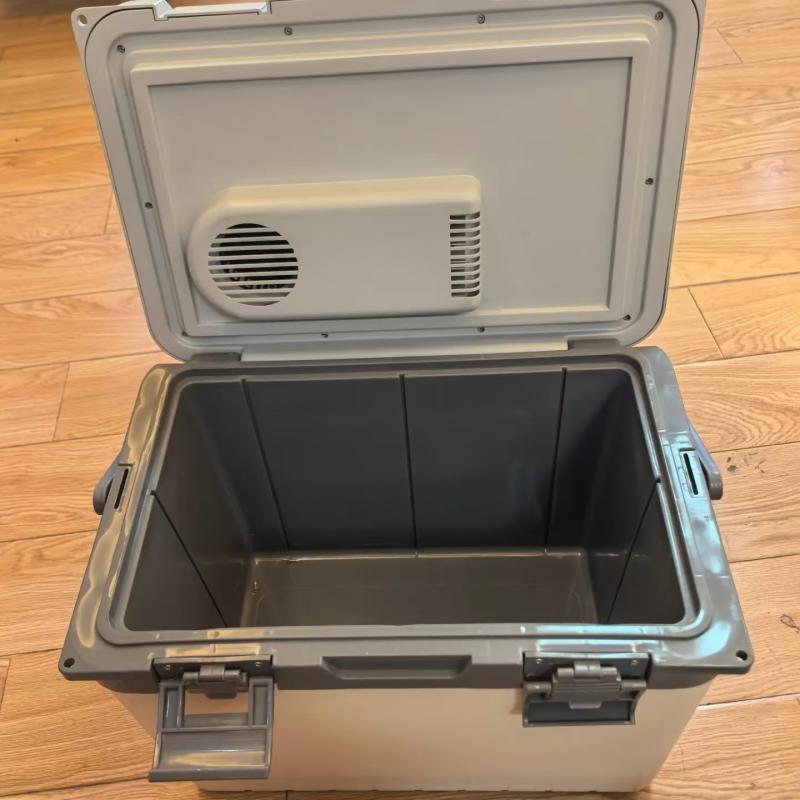

The Company's Latest New Product - Semiconductor Cooler Box

In the world of outdoor adventures and camping, having a reliable cooling solution is essential. Enter the latest innovation in portable refrigeration: the Semiconductor Cooler Box. This cutting-edge product combines the benefits of a plastic insulated ice box with the convenience of a rechargeable cooler box, making it an ideal choice for camping enthusiasts and outdoor lovers alike.

Image: https://www.koolyoungcooler.com/uploads/1%E5%9B%BE.jpg

The Semiconductor Cooler Box utilizes advanced semiconductor technology to provide efficient cooling…

Choose Zinc Die Casting For Superior Hardware

Finding Zinc hardware in the modern hardware market is quite common, and for good reason! Zinc die castings are widely used in the hardware industry due to the strength, durability, and versatility of Zinc alloys. Zinc die castings are made using a variety of zinc alloy materials.

Zinc die casted hardware is made by injecting molten zinc alloy into a mold cavity at high pressure, creating a precise and detailed Zinc…

Qingdao Sayhey Industry: Die Cast Heat Sinks - Features and Applications

Die cast heat sinks can be made in zinc or aluminum. Zinc is the easiest to die cast. Its tooling and unit costs are lower than those of aluminum. Zinc is also stronger, stiffer and tougher than aluminum. Die cast zinc heat sinks do not require plating, or plating can be done easily. Zinc is heavier than aluminum but provides the feel of high quality. On the other hand, aluminum…

Improving Indoor Air Quality: The Definitive Guide to Tongdy Monitoring Solution …

Introduction to Indoor Air Quality

Indoor Air Quality (IAQ) is crucial in maintaining a healthy work environment. As awareness of environmental and health issues rises, monitoring air quality is essential not only for green buildings but also for employee well-being and productivity. This summary outlines the benefits of Tongdy's air quality monitoring solutions, assisting building owners and managers in creating healthier, more eco-friendly indoor spaces.

The Importance of Monitoring Indoor Air Quality

Research…

More Releases for Wheel

Rail Wheel And Axle Industry Forecast to 2028 Global Market Analysis by Wheel Ty …

A rail wheel and axle is a type of wheel and axel that is specially designed for railways. Growing technological advancements in train networks and trains are compelling train manufacturers to invest heavy sums in R&D for the manufacturing of light materials for wheels and axles for passenger trains, freight trains, and short-distance trains. Rise in the production of locomotives in developing and developed countries are the major driving factor…

Section From Wheel Aligner Market Report 2019 Companies included 3D Wheel Aligne …

We have recently published this report and it is available for immediate purchase. For inquiry Email us on: jasonsmith@marketreportscompany.com

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2019 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2019 to 2025, etc. The report also provides detailed segmentation on the…

Section From Wheel Aligner Market Report 2018 Companies included 3D Wheel Aligne …

We have recently published this report and it is available for immediate purchase. For inquiry Email us on: jasonsmith@marketreportscompany.com

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025, etc. The report also provides detailed segmentation on the…

Global Commercial Automotive Wheel Market Forecast 2018-2025 Accuride Wheel, Bha …

Recently added detailed market study "Global Commercial Automotive Wheel Market" examines the performance of the Commercial Automotive Wheel market 2018. It encloses an in-depth Research of the Commercial Automotive Wheel market state and the competitive landscape globally. This report analyzes the potential of Commercial Automotive Wheel market in the present and the future prospects from various angles in detail.

The Global Commercial Automotive Wheel Market 2018 report includes Commercial Automotive Wheel…

Global Rail Wheel (Railway Wheel) Market 2018 - Lucchini RS, Rail Wheel Factory, …

The Global Rail Wheel (Railway Wheel) Industry 2018 Market Research Report is a professional and in-depth study on the current state of the Rail Wheel (Railway Wheel) industry.

Firstly, Rail Wheel (Railway Wheel) Market report provides a basic overview of the Rail Wheel (Railway Wheel) industry including definitions, classifications, applications and Rail Wheel (Railway Wheel) industry chain structure. Global Rail Wheel (Railway Wheel) Market analysis is provided for the international market…

Global Rail Wheel Market Consumption 2017 Trends By Product(Rolled Rail Wheel, F …

Scope Of Global Rail Wheel Market Research Report 2017

Global Rail Wheel Market Analysis, Status and Forecast 2022 Market Research Report contains a market overview of the industry which talks about market defination, product scope, revenue, growth opportunities, sales volumes and figures, growth estimation in coming years, current industry leaders and their sales/revenue metrics.

Request For Free Sample Report Here : https://www.reportsmonitor.com/request-sample/?post=486231

This report studies the global Rail Wheel market, analyzes and researches…