Press release

FocalSpec, Inc. introduces new high-precision Line Confocal Imaging Scanner for demanding 3D electronics AOI/AOM applications.

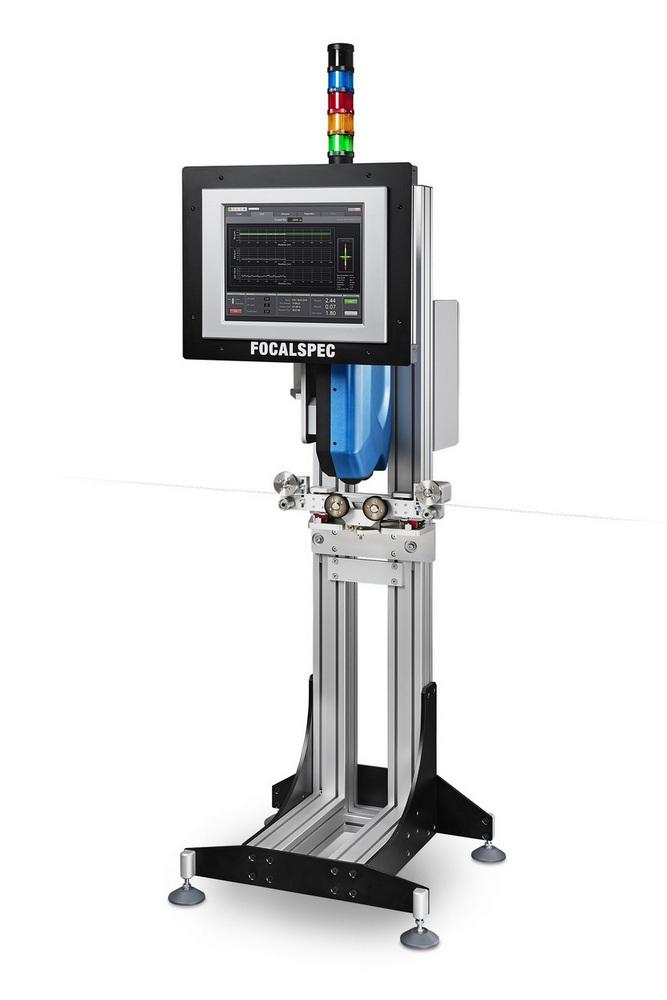

Cumming, GA (March 4, 2016) – FocalSpec, Inc., a supplier of Line Confocal Imaging (LCI) sensors and LCI-based 3D Automated Optical Inspection (AOI) and Automated Optical Measurement (AOM) systems to the electronics industry, is pleased to announce the formal North American launch of their new 3D Line Confocal Imaging Scanner.The new scanner is automatic and can be used in on-line, at line and laboratory applications on electronic and printed components, PCBs, assemblies, microdispensing, casings and other objects. It enables high-precision microtopographic 3D measurement of hard-to-measure surfaces where traditional technologies, such as lasers, do not perform satisfactorily.

“In addition to typical 3D measurement applications, our new scanner can also measure glossy, curved, slanted, high-contrast and transparent parts at sub-micron resolution,” said Juha Saily, Sales Manager for FocalSpec, Inc. “I’m excited that a newcomer like us is in a leading position to offer new technology that allows manufacturers to automatically scan materials and surfaces that have previously been unmeasurable.”

The launch of the Line Confocal Scanner coincides with FocalSpec exhibiting at IPC APEX EXPO 2016 in Las Vegas, March 15 – 17. The company and its scanner can be found at the booth # 1559.

FocalSpec, Inc. can be contacted at (770) 713-0837, email info@focalspec.com, website www.focalspec.com.

About FocalSpec:

FocalSpec, Inc. is a recently founded subsidiary of FocalSpec, Ltd. FocalSpec, Ltd, headquartered in Oulu, Finland, was founded in 2009 as a corporate spin-off from Technical Research Center of Finland (VTT). The company’s sensor products and 3D AOI/AOM systems are based on dual-axis Line Confocal Imaging technology that is patented worldwide.

FocalSpec, Inc. is a supplier of Line Confocal Imaging (LCI) sensors and LCI-based 3D Automated Optical Inspection (AOI) and Automated Optical Measurement (AOM) systems to the electronics industry.

1595 Peachtree Pkwy Ste 204-110

Cumming, GA 30041

USA

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release FocalSpec, Inc. introduces new high-precision Line Confocal Imaging Scanner for demanding 3D electronics AOI/AOM applications. here

News-ID: 325202 • Views: …

More Releases from FocalSpec, Inc.

FocalSpec introduces new Automatic Inline Roughness Measurement System for wire, …

Cumming, GA (September 7, 2016) – FocalSpec, Inc., a supplier of optical high-precision 3D scanning sensors and solutions, is pleased to announce the formal North American launch of their new non-contact wire, cable, and filament surface roughness measurement system, the MicroProfiler MP 900.

The MP 900 is based on FocalSpec’s patented Line Confocal Imaging (LCI) technology that enables accurate in-production roughness measurement from a fast moving surface of any type…

FocalSpec, Inc. launches a range of new high-resolution 3D Line Confocal Imaging …

Cumming, GA (June 7, 2016) – FocalSpec, Inc., a supplier of optical 3D surface measurement solutions with sub-micron level resolution, is pleased to announce the formal North American launch of their new 3D Line Confocal Imaging (LCI) sensors.

The new sensors can be integrated into both in-production and standalone 3D scanning systems. They enable a non-contact measurement of surface profile, 3D dimensions, surface roughness, flatness, layer thickness, air gaps etc.…

More Releases for FocalSpec

Confocal Sensor Systems Market Research With Size, Growth, Key Players, Segments …

LOS ANGELES, United States: The global Confocal Sensor Systems market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Confocal Sensor Systems market. For instance, the market dynamics section digs deep into the drivers, restraints,…

Inline Monitoring Market Growth Factors, Restraints, Advancements and rising Tre …

Inline Monitoring Market – Snapshot

The inline monitoring market is anticipated to boost various growth opportunities in the upcoming years. The market is estimated to promote expansion on the back of enforcement of critical regulations and laws that are legislated by government bodies. The motive of these regulations is to comply with the quality standards of in the pharmaceutical industry for quality packaging.

Request Sample Copy @ https://www.tmrresearch.com/sample/sample?flag=B&rep_id=5432

The pharmaceutical industry is likely…

Inline Monitoring Market Giants Spending Is Going To Boom | Keyence Corporation, …

Inline Monitoring Market – Snapshot

The inline monitoring market is anticipated to boost various growth opportunities in the upcoming years. The market is estimated to promote expansion on the back of enforcement of critical regulations and laws that are legislated by government bodies. The motive of these regulations is to comply with the quality standards of in the pharmaceutical industry for quality packaging.

Request Sample Copy @ https://www.tmrresearch.com/sample/sample?flag=B&rep_id=5432

The pharmaceutical industry is likely…

Inline Monitoring Market 2028 | Emerson Electric, LMI Technologies

Inline Monitoring Market – Introduction

Inline monitoring refers to the use of stationary sensors mounted outright in the industrial process for sensing the variables such as viscosity, density, color, temperature, or pH level.

Unmatched efficiency of inline monitoring to measure the shifting parameters in real time aids in the detection and damage control of produced goods, which aids in saving significantly on the production cost.

Get Sample Copy of the Report @ https://www.tmrresearch.com/sample/sample?flag=B&rep_id=5432

Inline…

FocalSpec introduces new Automatic Inline Roughness Measurement System for wire, …

Cumming, GA (September 7, 2016) – FocalSpec, Inc., a supplier of optical high-precision 3D scanning sensors and solutions, is pleased to announce the formal North American launch of their new non-contact wire, cable, and filament surface roughness measurement system, the MicroProfiler MP 900.

The MP 900 is based on FocalSpec’s patented Line Confocal Imaging (LCI) technology that enables accurate in-production roughness measurement from a fast moving surface of any type…

FocalSpec, Inc. launches a range of new high-resolution 3D Line Confocal Imaging …

Cumming, GA (June 7, 2016) – FocalSpec, Inc., a supplier of optical 3D surface measurement solutions with sub-micron level resolution, is pleased to announce the formal North American launch of their new 3D Line Confocal Imaging (LCI) sensors.

The new sensors can be integrated into both in-production and standalone 3D scanning systems. They enable a non-contact measurement of surface profile, 3D dimensions, surface roughness, flatness, layer thickness, air gaps etc.…