Press release

SCHWING Technologies: thermal cleaning of filter bundles for the packaging industry

Neukirchen-Vluyn (Germany), September 4, 2019. The cleanliness of filter bundles and filter candles is essential when it comes to quality of the film. The packaging industry used to replace these filters, but today, they are often cleaned for reuse. Why? Depending on the degree of filtration, investments of roughly 600 Euro per filter candle are not uncommon. Cleaning in a VACUCLEAN vacuum pyrolysis system and other post-treatment equipment for reuse, on the other hand, is much cheaper. Systems gently remove all plastic residues from very fine filters. With regular cleaning, filter quality is guaranteed for best production results. Materials such as BOPP, BOPET and BOPA can be removed.Complete cleaning shops

SCHWING Technologies, based in Neukirchen-Vluyn in the Lower Rhine region of Germany, is an expert for environmentally friendly and safe cleaning of machine tooling. The German company has offered systems to the industry for 50 years and is the only supplier worldwide for complete and customized cleaning equipment solutions. "We always tailor the cleaning shops very individually to the needs of our customers", says Virgilio Perez Guembe, Head of Sales at SCHWING, "with many years of know-how we guarantee maximum cleanliness - without any damage to the filters."

Worldwide sales and testing at the company headquarters

SCHWING sells its complete process solutions worldwide. The company also provides cleaning services in Germany and invites customers to test the cleaning processes at its headquarters in Neukirchen-Vluyn. "We are constantly developing our equipment to achieve optimum results", explains Perez Guembe,"and we are tailoring our cleaning processes to new material mixtures and metal filter designs.”

Individually tailored cleaning process

The cleaning process includes several individually tailored steps, the parameters of which are optimally adjusted: These include first cleaning in a VACUCLEAN vacuum pyrolysis system, post-cleaning processes and final checks.

Safe and gentle vacuum pyrolysis

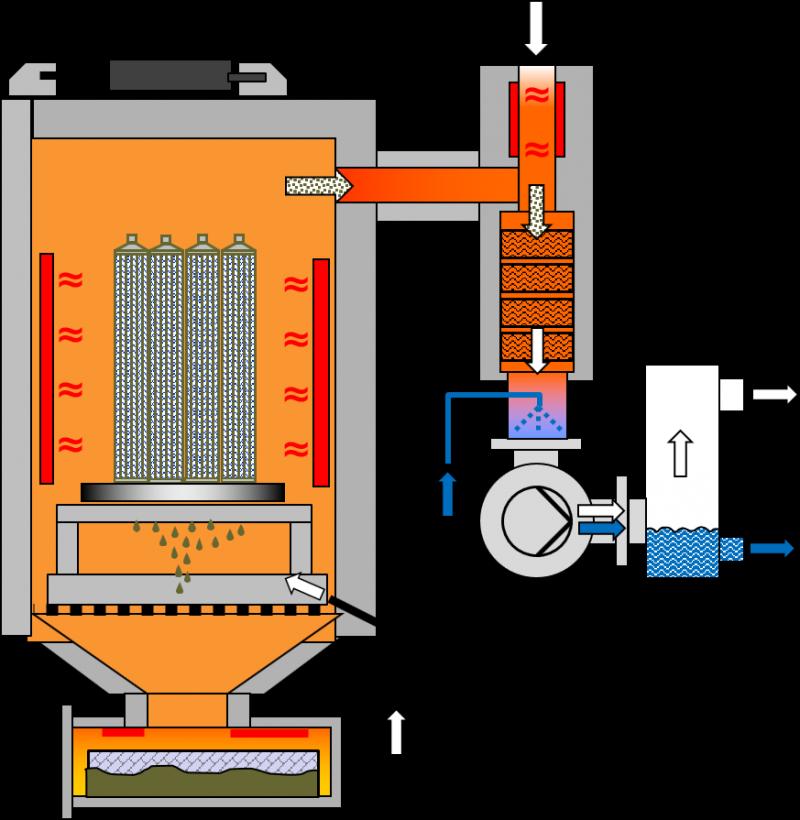

Workflow of the cleaning process starts with disassembly of the filter bundle. "Then, we carry out the melting process in our VACUCLEAN vacuum pyrolysis system”, explains Perez Guembe. The experienced expert considers all cleaning factors, such as the positioning of the filter bundle, heating time, temperatures and duration of pyrolysis and oxidation. "Even the highest qualities can be cleaned with this system. In a very gentle way, we thermally melt and decompose organic material from temperature-resistant metals."

The fully automatic cleaning process of the VACUCLEAN takes place in an electrically heated vacuum cleaning chamber. Temperature of the filter bundle is measured directly, which is heated particularly slowly and gently. Here, a large percentage of adhering plastic melts off and flows out. At approximately 450 degrees Celsius, the decomposition of the remaining plastic takes place – remaining carbon is finally removed by introducing air (oxidation). An intelligent sensor system controls the oxidation process, so excess temperatures do not occur at any time.

Individualized post-treatment

The experts at SCHWING also offer tailor-made solutions for post-treatment. "Although the thermal cleaning systems remove all organic impurities, inorganic residues, such as residual ash, remain in the filter bundles", explains Perez Guembe. "Special post-treatment methods can remove these absolutely safely.” Post-treatment is always carefully matched to the individual filters and cleaning processes of the customer. Some solutions used are high-pressure water cleaning devices and an ultrasonic bath.

High-pressure post-cleaning and disassembly of the filter bundles

Manual high-pressure post-cleaning processes with water are suitable for removing further residues. The mechanisms for this are temperature and water pressure. Perez Guembe: "During the next step, filter bundles are broken down into individual candles and treated in a backwashing system in the form of back flushing and pressure. In this step, inorganic residues are removed from the inside and outside. Important parameters here are pressure and temperature of the flushing.

Ultrasonic bath, rinsing and drying

In the ultrasonic bath and with subsequent rinsing, the ultra-fine and sensitive filter candles are freed from further residual contamination, especially in difficult-to-access areas. In this step, SCHWING recommends that a number of specifications be taken into account – temperature, type of liquid, additives, filter position, ultrasonic frequency and cleaning time. The filters are then dried in a drying oven. Essential key data is temperature, position of the filter cartridges and drying time.

Inspection and documentation

Bubble tests document whether a filter candle is faultless or mechanically damaged, and a liter per minute (LPM) flow test also verifies the result. Characteristic parameters are liquid (water or isopropanol), test medium and test pressure. In the case of water, a new test is carried out in a drying oven; in the case of isopropanol, in an evaporation fixation. A final weight check confirms perfect cleaning of the filter cartridge.

Environmentally and user-friendly solution

The entire cleaning line is environmentally friendly, has low operating costs and is powered by only electricity and water. It is easy to install and can be quickly trained by SCHWING service team. Perez Guembe explains, "Another advantage for our customers in the packaging industry is that the service life of filter candles and filter bundles is significantly increased and systems can be operated under less pressure. This ensures not only the filter quality, but also the film quality in the long-term".

Further information: https://www.thermal-cleaning.com/en/cleaning-systems-and-accessories/vacuum-pyrolysis-systems.html

Keywords: Filter candles, Filter bundles, Filter cleaning, Plastic removal, VACUCLEAN, Vacuum pyrolysis system, Vacuum pyrolysis plant, Vacuum pyrolysis furnace, Thermal cleaning

Press contact:

Nicola Leffelsend

SCHWING Technologies GmbH

Oderstraße 7

47506 Neukirchen-Vluyn

Germany

T +49 2845 930 146

redaktion@schwing-tech.com

www.schwing-technologies.de

SCHWING Technologies

SCHWING Technologies has been operating for 50 years and is the worldwide technological leader for high-temperature systems for thermal cleaning, thermo-chemical finishing and heat treatment of metal parts and tools. The owner-managed company designs, manufactures, and operates systems at its headquarters in Neukirchen-Vluyn in Germany's Lower Rhine region. Built upon the achievements of German engineering, the medium-sized business is globally the best-known specialist in the removal of plastics. Among SCHWING’s approximate 2,500 international clients are companies from the plastics and fiber industries, as well as from the chemicals and automobile sectors. For every cleaning need, the company with its approximately 80 employees offers the most economically, ecologically and qualitatively best technology and cleaning solution. SCHWING is also a reliable service partner for contract cleaning by processing more than 250,000 tools and parts each year to the highest environmental and qualitative standards. So far, there has not been a single component that we have not been able to free from polymers and inorganic contaminants, confirm the three managing directors Ewald Schwing, Thomas Schwing and Alfred Schillert. Founded in 1969, the company celebrates its 50th anniversary in 2019 and opened SCHWING Technologies North America Inc., a new sales company in the USA, this year.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SCHWING Technologies: thermal cleaning of filter bundles for the packaging industry here

News-ID: 1829647 • Views: …

More Releases from SCHWING Technologies GmbH

New at the trade fair K 2019: SCHWING Technologies cleans tall filter candles up …

Neukirchen-Vluyn (Germany), October 8, 2019. At this year's K 2019 in Düsseldorf from October 16 to 23, SCHWING Technologies will be presenting its extended vacuum pyrolysis system VACUCLEAN 0917 for the first time (Hall 9/booth A77). With this system, the German expert for environmentally friendly and energy-efficient thermal cleaning systems is primarily targeting users of especially tall filter candles and bundles up to 170 cm high and 0.90 cm in…

ITMA 2019: Predictive maintenance secures production processes in the fiber indu …

Neukirchen-Vluyn (Germany), May 2, 2019. The production of textiles and clothing will be the focus of this year's ITMA 2019 in Barcelona. From June 20 to 26, 2019, the German specialist SCHWING Technologies will be presenting thermal cleaning solutions for polymer-contaminated production tools. In hall 7 / booth C120, SCHWING experts, Managing Director Thomas Schwing and Head of Sales Virgilio Perez Guembe, will inform about the potentials and advantages of…

More Releases for VACUCLEAN

New at the trade fair K 2019: SCHWING Technologies cleans tall filter candles up …

Neukirchen-Vluyn (Germany), October 8, 2019. At this year's K 2019 in Düsseldorf from October 16 to 23, SCHWING Technologies will be presenting its extended vacuum pyrolysis system VACUCLEAN 0917 for the first time (Hall 9/booth A77). With this system, the German expert for environmentally friendly and energy-efficient thermal cleaning systems is primarily targeting users of especially tall filter candles and bundles up to 170 cm high and 0.90 cm in…

ITMA 2019: Predictive maintenance secures production processes in the fiber indu …

Neukirchen-Vluyn (Germany), May 2, 2019. The production of textiles and clothing will be the focus of this year's ITMA 2019 in Barcelona. From June 20 to 26, 2019, the German specialist SCHWING Technologies will be presenting thermal cleaning solutions for polymer-contaminated production tools. In hall 7 / booth C120, SCHWING experts, Managing Director Thomas Schwing and Head of Sales Virgilio Perez Guembe, will inform about the potentials and advantages of…

Chinaplas 2019: SCHWING Technologies cleans tools and machine parts for the plas …

Neukirchen-Vluyn (Germany), April 30, 2019. From May 21 to 24, 2019, SCHWING Technologies will once again be exhibiting at Chinaplas 2019, the leading Asian plastics trade fair, in Guangzhou, China. With its green-cleaning systems, the German plant manufacturer has been an internationally successful specialist for the removal of plastics and polymers for 50 years. SCHWING experts Virgilio Perez Guembe, Sunil Chalishajar and Samuel Zhang will be providing information in hall…

Compounding World Expo 2019: SCHWING Technologies presents its thermal cleaning …

Neukirchen-Vluyn (Germany), April 25, 2019. Plastic additives and compounding are the central topics of Compounding World Expo in Cleveland, Ohio on May 8-9, 2019. As a supplier of thermal cleaning systems, the German company SCHWING Technologies GmbH, together with its subsidiary SCHWING Technologies North America Inc., will also be exhibiting at the international trade show. With their cleaning systems, all polymers and plastic additives can be easily removed from machine…

SCHWING Technologies is attending Indointertex 2018 with thermal cleaning system …

Neukirchen-Vluyn, April, 4, 2018. Indointertex, the international trade fair in Jakarta that takes place between April 4-7, 2018, will be all about the clothing and textile industry along with its machines and accessories.

The cleaning expert SCHWING Technologies recommends its VACUCLEAN thermal vacuum pyrolysis system to remove adhering plastic waste with virtually no residue.

At the PT. Jabar Mulia Engineering booth 105, SCHWING expert Sunil Chalishajar will inform visitors about…

24/7 Service Unit of SCHWING Technologies

Neukirchen-Vluyn, 14.03.2018. Since 1969, the name SCHWING Technologies has stood for plant construction and thermal cleaning systems. “Our customers throughout Germany, Switzerland, France and the Benelux countries additionally benefit from our professional cleaning services for tool and machinery parts contaminated with plastic residues,” explains Reinhold Bergmann, Head of SCHWING Cleaning Service. At the site in Neukirchen-Vluyn, he and coordinator Viktor Brandner are the experienced and committed leaders of the corporate…