Press release

Manual lubrication, flexible and ergonomic: EOS Move by Eckardt

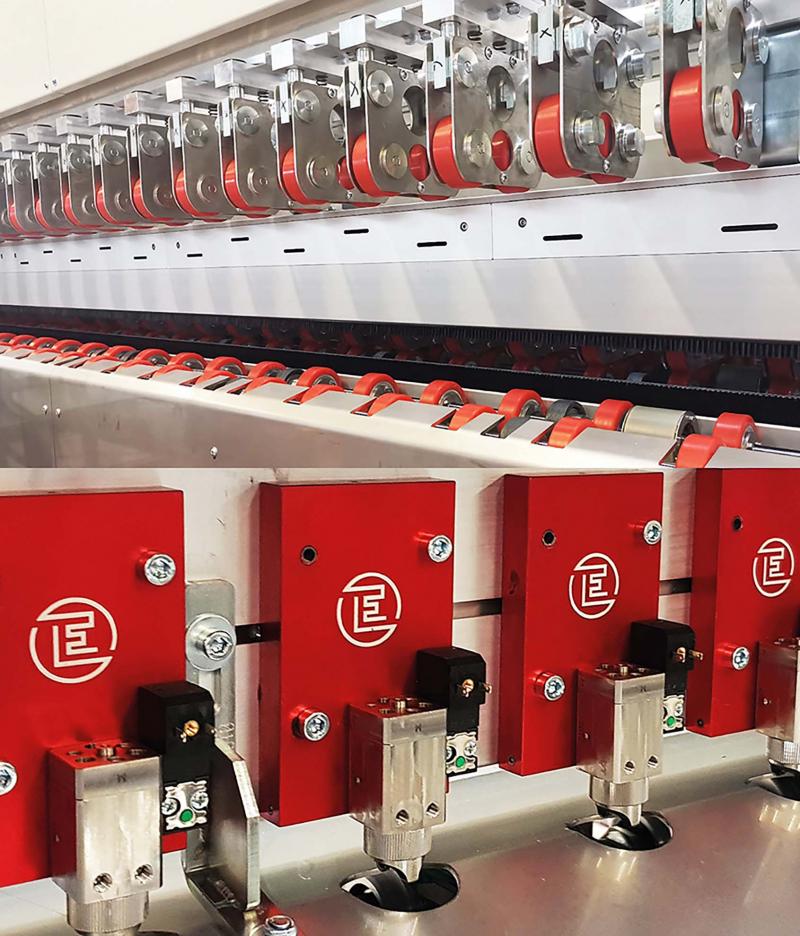

Bretten/Germany, July 2019: Eckardt Systems, manufacturer of lubrication, cleaning and preservation systems for industrial production, introduces a new spray nozzle system for manual blank lubrication: EOS Move.In comparision with conventional systems EOS Move swaps roles, since it is the spray bar that moves – not the blank. This enables the entire process – blank insertion, blank lubrication and blank removal – to be conducted requiring significantly less working space, and the machine operator to work much more ergonomically.

Measuring ca. 2,20 x 1,60 x 1 m (H x L x W) and weighing some 500 kg in the standard version, the EOS Move system can be fixed on the floor or mounted on reels for mobile use. It processes blanks of up to 600 x 600 mm in size, the seating of which - as well as the entire system - can be adjusted according to individual user requirements. The standard configuration includes 2 x 6 spray nozzles attached to the spray bar.

Just as in a scanner the spray bar traverses the blank surface and applies the lubricant. While reversing, the operator or roboter changes the blanks at freely selectable intervals. The oil reservoir/oil supply, exhaust equipment and control system are permanently attached to the machine. This also allows for flexible, customer-specific configurations, e.g. in the shape of several oil reservoirs connected „in series“. The system applies standard technology and components manufactured by Eckardt such as the EDS control unit introduced in early 2018.

„On site one is often confronted with adverse conditions while manually operating a lubrication system,“ says Daniel Assmann, head of the sales department at Eckardt Systems. „This is usually the case when the blanks move through the machine and the operator has to insert and remove them while taking a less than ideal working position. In the new EOS Move we have eradicated this flaw, since it is no longer required to move back and forth in tight spaces and change one’s grip in a rather cumbersome way.“

Eckardt Systems GmbH

Stefan Müller-Ivok

Westliche Gewerbestr. 2

75015 Bretten, Germany

Phone: +49 7252 9420-0

Mobile +49 176 5791 2240

E-Mail: s.mueller-ivok@eckardt-systems.com

Founded in 1992 Eckardt Systems manufactures lubrication systems as well as cleaning and preservation systems for industrial production. Today, the second generation of this family-run company employs some 30 people.

The product range includes roller lubricators, squeeze-on lubricators and spray systems, available in different versions for different widths of materials. Eckardt also produces oil mist separators and complete systems to customer-specific specifications. as well as customized systems, for example for hydroforming (IHU). In addition, the company offers numerous spray and spit nozzles as well as dosing systems for the lubrication segment. We also supply lubricants and oils under our own brand name ROTOL.

Furthermore, Eckardt serves the process field preserving with corrosion protection systems, which are used primarily in the hot forming process as well as to prepare parts and assemblies for transport. The dry cleaning systems for sheet metal and blanks offer an economical, environmentally-friendly low maintenance alternative to the wet cleaning systems often in use.

Eckardt produces all of its systems and plant at the company headquarters in Bretten, near Karlsruhe, Germany. The depth of our in-house manufacturing capabilities is widely recognized. We run our own electronics development department as well as a nozzle testing laboratory dedicated to optimizing spraying processes and performing fault analyses in customer systems.

Eckardt offers its customers comprehensive advice on all aspects of the lubrication process beginning with an extensive survey of the production environment through to the best-possible integration in upstream and downstream process steps. In the field of engineering Eckardt technology is adapted to precisely suit existing conditions and processes on site and can be individually modified to meet requirements. Installation, commissioning and general system refurbishments round off the spectrum.

The company serves customers in all regions of the world. We focus on the automotive and supplier industries; however, small companies offering sheet metal punching services also profit from our know-how as manufacturer of quality products.

www.eckardt-systems.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Manual lubrication, flexible and ergonomic: EOS Move by Eckardt here

News-ID: 1813391 • Views: …

More Releases from Eckardt Systems GmbH

Blechexpo 2019: Precision lubrication, corrosion protection, retrofitting for pr …

Bretten, Germany - Eckardt Systems highlights a variety of topics at the upcoming Blechexpo trade fair in Stuttgart. The specialist for lubrication, cleaning and preserving technology introduces a new control concept for its lubrication systems. The multifaceted issue of corrosion protection also takes center stage as do innovative retrofitting concepts for press shops. In addition, the company shows a budget version of the EOS spray lubrication system.

The revised system control…

More Releases for EOS

EOS Earns India's Most Valuable Workplace ® award by WCRC

Summary: Eureka outsourcing solutions, a world leader in the space of delivering outsourcing services, has recently received the coveted title of 'India's Most Valuable Workplace®'. As EOS keeps pace with the velocity of change the BPM sector is witnessing, EOSite influencers speak about the culture fostered at EOS that makes their employees' workday productive as well as rewarding.

Eureka Outsourcing Solutions was awarded the title of 'India's Most Valuable Workplace' by…

Tabetha Sheaver Joins EOS as a Professional Implementer

Tabetha Sheaver, a well-known and highly respected business consultant, has joined the Entrepreneurial Operating System® (EOS®) as a Professional Implementer. Sheaver will continue to serve as owner of St. Louis consulting firm Plus Delta and as a Fractional COO for a handful of select companies.

A business coach, facilitator and trainer with over 20 years of experience, Sheaver has consulted with Fortune 500 corporations but focuses the majority of her time…

3D Printing System Market Regional Outlook, Competitive Strategies, Factors Cont …

LOS ANGELES, United States: The research study presented in this report offers complete and intelligent analysis of the competition, segmentation, dynamics, and geographical advancement of the global 3D Printing System market. It takes into account the CAGR, value, volume, revenue, production, consumption, sales, manufacturing cost, prices, and other key factors related to the global 3D Printing System market. The authors of the report have segmented the global 3D Printing System…

NEW PRODUCT LAUNCH: THE GRAND-EOS HYPERSPECTRAL CAMERA AND PLATFORMS

APPLICATION EXAMPLES:

» Photovoltaic characterization (( It allows the optical characterization of a wide variety of 2nd and 3rd generation solar cells )

» Mineral analysis

» Forensic

» Food and plants sorting

GRAND-EOS combines a hyperspectral microscopy system with a hyperspectral wide-field imaging platform, giving access to micro and macro modalities with both VNIR (400-100 nm) and SWIR (900-1700 nm)…

Eos Group Releases Piping Database 2011

Scottsdale, AZ – June 30, 2011

Eos Group, Inc. has announced the release of the 2011 Piping Database. The Piping Database is designed to support construction cost estimating for utilities, owners, design engineers and contractors in the area of piping for facilities and industrial plants.

Designed for use with Sage Timberline Office Estimating, the database contains over 63,000 items, 67 assemblies and 1 parametric model. The new release is a…

Eos P6 Integrator Version 2.0

Scottsdale, AZ – June 1, 2011

Eos Group Inc. announced the second release of P6 Integrator labeled P6 Integrator Version 2.0.

P6 Integrator brings together the disciplines of estimating and scheduling of construction projects while eliminating effort and risk. The new version will allow more clients to benefit from its dynamic functionality. Whereas version 1.0 was only compatible with Primavera P6 Project Management Version 6.2.1, version 2.0 also now…