Press release

SABIC’s thermoforming portfolio successfully supports customers in meeting their design and awareness challenges

SABIC’s thermoforming portfolio successfully supports customers in meeting their design and awareness challenges

“Our customers are looking for lightweight packaging with an eye-catching design and an excellent impact. By using the SABIC® PP range for Thermoforming we can meet and even surpass these expectations, thus supporting and improving our customers’ brand awareness,” says Merete Rosendahl, Development Manager, Færch Plast.

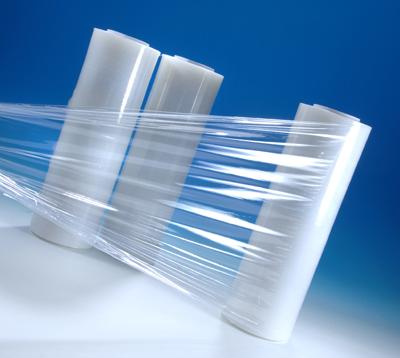

As well as the appearance of packaging, its “green” aspect is becoming increasingly important for consumers, more and more of whom are consciously choosing to buy environmentally friendly products and packaging. SABIC understands this trend and has designed the homopolymer grade SABIC® PP 527K to meet these requirements. “SABIC® PP 527K opens up new down gauging opportunities and improves the conversion economics which results in a considerably reduced carbon footprint for our customers,” says Tjerk Lenstra, SABIC Technical Marketing. “This new generation of SABIC® PP for thermoforming offers converters down gauging possibilities of up to 10-15% which provides them with significant material and energy savings. Without compromising on quality and safety, SABIC’s PP grades are the product of choice when it comes to sustainable production and consumption.”

SABIC’s broad PP product portfolio – consisting of homopolymers, impact copolymers and random polymers – is widely applied within the thin wall packaging industry. “At SABIC we not only understand the challenges of converters but also the key drivers of their customers, the brand owners,” continues Lenstra. “Specifiers and converters such as Færch Plast demand tailor made solutions that fit with their market strategy and our portfolio can fulfil both their demands.”

SABIC is continuously looking for new solutions that meet the requirements of our customers along the complete value chain. “We are a value driven partner, supporting our customers’ success by providing them with material solutions that respond to the market trends in plastic packaging, be they PP, PE, PET or PS, ” explains Lenstra.

ENDS

Notes to Editors

About SABIC

Saudi Basic Industries Corporation (SABIC) ranks among the world’s top six petrochemical companies. The company is among the world’s market leaders in the production of polyethylene, polypropylene and other advanced thermoplastics, glycols, methanol and fertilizers.

SABIC recorded a net profit of SR 9 billion (US$ 2.4 billion) in 2009. Sales revenues for 2009 totaled SR 103 billion (US$ 27 billion). Total assets stood at SR 297 billion (US$ 79.2 billion) at the end of 2009.

SABIC’s businesses are grouped into Chemicals, Polymers, Performance Chemicals, Fertilizers, Metals and Innovative Plastics. SABIC has significant research resources with six dedicated Technology & Innovation Centers in Saudi Arabia, Europe, the USA and India.. The company operates in more than 40 countries across the world with 33,000 employees worldwide.

The company has 19 world-scale complexes in Saudi Arabia. Elsewhere, SABIC manufactures on a global scale in the Americas, Europe and Asia Pacific. SABIC’s overall production has increased from 35 million metric tons in 2001 to 59 million metric tons in 2009.

Headquartered in Riyadh, SABIC was founded in 1976 when the Saudi Arabian Government decided to use the hydrocarbon gases associated with its oil production as the principal feedstock for production of chemicals, polymers and fertilizers. The Saudi Arabian Government owns 70 percent of SABIC shares with the remaining 30 percent held by private investors in Saudi Arabia and other Gulf Cooperation Council countries.

About SABIC in Europe

In Europe, SABIC has 13 world-scale production facilities which manufacture innovative plastics, polyethylenes, polypropylenes and chemical products. Throughout Europe, SABIC employs approximately 6000 people.

The main European offices for three of SABIC’s strategic business units are located in The Netherlands - Innovative Plastics (Bergen op Zoom), Polymers (Sittard) and Chemicals (Sittard). They operate an extensive network of local sales offices and logistical hubs throughout Europe which are also responsible for the sales of products manufactured elsewhere in the world.

SABIC’s European research facilities form part of the global Technology and Innovation organization and can be found in the Netherlands (Geleen and Bergen op Zoom) and Spain (Cartagena).

About Færch Plast

Færch Plast in Holstebro, Denmark, was established in 1969. Over the years the company has secured a strong market position and is well known for developing and manufacturing high-quality packaging for foods. The company extrudes film and thermoform packaging 24/7, 365 days a year. In addition to its production facilities and administration in Holstebro, the company has sales offices in the UK and in France as well as a factory in the Czech Republic. For further information, please visit www.faerchplast.dk.

Media Notes

• As an acronym, SABIC should be all caps whenever it appears in print.

• ® Trademark of SABIC

Brigitta de Vries

Marketing Solutions

Box 6

2950 Kapellen

Belgium

T +31 164 317 000

E bdevries@marketingsolutions.be

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SABIC’s thermoforming portfolio successfully supports customers in meeting their design and awareness challenges here

News-ID: 127977 • Views: …

More Releases from SABIC Europe

SABIC® LDPE UMS pushes the limits in performance, cost-efficiency and sustainab …

Sittard, the Netherlands – November 2, 2010 – SABIC – a leading player in the global plastics industry – today launched its new foam line, SABIC® LDPE Ultra Melt Strength (UMS), at the K2010 tradeshow in Düsseldorf, Germany (Hall 6, Stand D42).

SABIC® LDPE Ultra Melt Strength (UMS) incorporates high-performing Low Density Polyethylene (LDPE) materials that provide a high insulating capacity for building applications and an outstanding shock-absorbing capability for packaging…

SABIC’s smart concept in multi-layer film packaging raises the levels of perfo …

Sittard, the Netherlands – October 27, 2010 – SABIC, a leading player in the global plastics industry, today unveiled a pioneering concept in low-density polyethylene and linear-low-density polyethylene (LD/LLDPE) films at the K2010 tradeshow in Düsseldorf, Germany

(Hall 6, Stand D42).

This milestone innovation marks a new approach to leveraging SABIC’s world-class polyolefin portfolio. Among numerous benefits, it produces smart resin combinations offering converters significant material and energy savings while…

More Releases for SABIC’s

SABIC’s new LNP™ ELCRES™ EXL resin delivers superior flame retardance

The implementation of the International Electrotechnical Commission’s new IEC 62368-1 safety standard for consumer electronics is prompting many manufacturers to seek higher-performing flame-retardant (FR) materials. Realme, a leading Chinese smartphone manufacturer, has selected SABIC’s new LNP™ ELCRES™ EXL7414 copolymer resin for the battery enclosure of its C25 phone to achieve UL 94 V0 FR compliance at 0.6mm, addressing the new IEC standard. Additionally, the superior flame retardance of the new…

SABIC’s new PP extrusion line is now operational in The Netherlands

SABIC, a global leader in the chemical industry announced today the start-up of its new Polypropylene (PP) extrusion facility in Geleen, The Netherlands. This new extrusion line adopts state-of-the-art process technology to produce SABIC® PP products and the next generation PP copolymers and underlines the company’s drive to provide advanced materials that can support customers developing new lightweight applications in industries such as packaging, appliances, automotive, healthcare and help them…

SABIC’S DEDICATED LDPE FOAM GRADES FOR MEAF AND ASIA

Polymeric foams are widely used in numerous areas that encompass building & construction, automotive, packaging, sports & leisure, and more. Enhanced physical properties and excellent foamability of the polymers are key in enabling more efficient material usage and energy savings.

At the beginning of 2016, during the Chinaplas event, SABIC announced the launch of two new dedicated foam grades, SABIC® LDPE HP2024JDF and HP2024NDF, for Middle East, African, and Asian…

SABIC’s commitment to sustainability reflected at Doha expo, led by CEO

The Saudi Basic Industries Corporation (SABIC) is participating in the Qatar Sustainability Expo, which coincides with the United Nations Framework Convention on Climate Change (UNFCCC), in Doha from November 26 to December 7.

Abdullah bin Hamad Al-Attiyah, President of COP18/CMP8, visited the SABIC stand during the inaugural ceremonies. He was accompanied by Dr. Mohammed bin Saleh Al-Sada, Minister of Energy and Industry, and Christiana Figueres, UNFCCC Executive Secretary. They were received…

SABIC’s bimodal HDPE family meets the increasing challenges of the film indust …

Sittard, the Netherlands – May 2, 2012 – Production of high quality thin blown film is possible with a family of advanced bimodal high density polyethylenes (HDPE) from SABIC. There are currently two grades in the family, SABIC® HDPE FI0644 and a higher density grade with higher flow, SABIC® HDPE FI1157.

Both grades have high molecular weight and a broad molecular weight distribution. These characteristics translate into a good processability that…

SABIC’s Xenoy iQ* for Canon Scanner Housing

BERGEN OP ZOOM, The Netherlands – April 12, 2012 – At NPE 2012

SABIC’s Innovative Plastics business announced that Canon Electronics Inc. – a global leader in imaging and optical products – has selected high-performance Xenoy iQ* ENH resin with up-cycled post-consumer recycled (PCR) content for the housing of its new “imageFORMULA DR-M160” high-speed document scanner. Canon Electronics previously used a polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) material without any PCR content for its scanner…