Press release

Platform economy as the basis for business intelligence (BI) - software platform for AI and machine learning

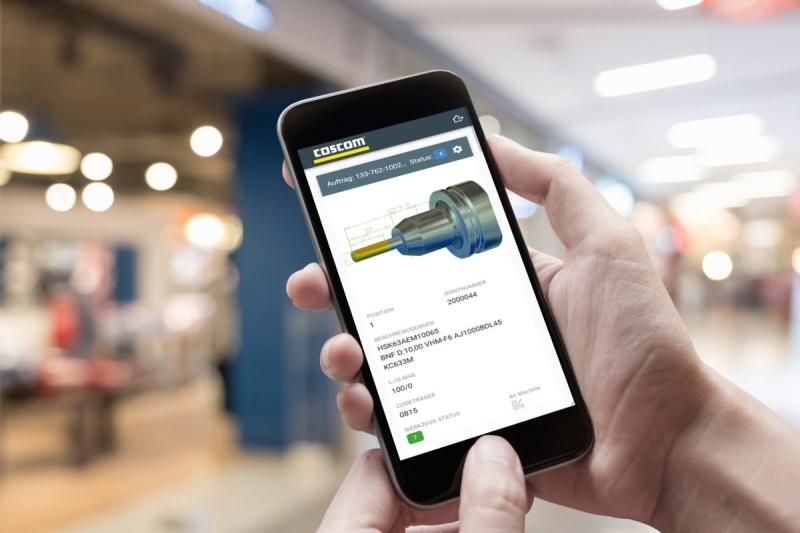

The COSCOM ECO system guarantees a platform economy as the basis for Business Intelligence (BI). (© COSCOM Computer GmbH)

"Hey Alexa, how can you support industrial production?" This question is difficult to answer in general, but it is very easy to answer for specific use cases. Why shouldn't work preparation receive an answer to this question from an IT platform: "Is there a valid NC program for this article? Are all tools sufficiently available? And what tool measurement data is available?" It is about knowledge from the perspective of production planning for certain work steps that could only be researched at great expense without IT support. This brings up the topic of platform economy, in which experts provide their contributions in an orchestrated manner.

Models for digital ecosystems are based on our knowledge of natural ecosystems, particularly with regard to aspects of competition and different forms of cooperation. A digital ecosystem is a distributed, adaptable, open socio-technical system with characteristics of self-organization, scalability and sustainability, inspired by natural ecosystems. The COSCOM ECO system for the machining industry with its central database platform supports this approach in the long term: all production-relevant data is brought together in a common source of truth and, thanks to end-to-end digitalization, can be accessed by all "data consumers" across the company and store floor.

Central data pool for machine learning and business intelligence (BI)

COSCOM is aware of the potential of machine learning and business intelligence: "Machine learning can be used to optimize future work processes based on experience and knowledge from past data pools. For example, a master computer could plan an order on its own and orchestrate the necessary resources," says Christian Erlinger, Managing Director of COSCOM Computer GmbH from Ebersberg near Munich, encouraging reflection.

In addition, the production information consolidated by the central COSCOM database platform can be used to tackle general, cross-order efficiency issues - e.g. evaluating the potential benefits of a new machining center, including all additional resources required. This would make it possible to analyze the benefits of new technologies, such as trochoidal milling, which involves working with a high depth of cut, including suitable machining strategies. And indeed, such Business Intelligence (BI) projects have already been successfully implemented by COSCOM experts.

Breaking new ground - without risk and on the basis of valid data

Christian Erlinger explains the background: "We evaluated the use of a new machine in a BI project to increase efficiency. It turned out that the new technology of trochoidal milling was not being used enough. The reason: the existing CAM program was only changed minimally for a follow-up order because the geometric characteristics of the components had only changed slightly - the basic machining strategy was not called into question." In other words, there was no reprogramming, instead the company relied on the reuse of existing CAM programs - the result: everything remained the same: "Our BI application showed which milling technologies were used how often and which potentials were not exploited."

A similar analysis revealed how many tools should be stocked and in what quantities. Many aspects play a role in the search for the ideal tool stock, for example the delivery time: although a tool is not used very often, several of them should be kept in stock because the delivery time is long. A BI application supported by the COSCOM database platform brings such interdependencies to light and thus helps to optimize decision-making in complex contexts.

Platform economy: master big data and use it easily

The software experts at COSCOM use MS PowerBI, among others, for demanding projects with large amounts of data (keyword "big data"). The COSCOM database platform provides the necessary data structure. However, it does not have to be this Microsoft product; any other BI system can also be used. Christian Erlinger explains: "With the help of the COSCOM ECO system, the production data becomes the user's 'treasure', where the data is available for retrieval with object dependencies."

COSCOM offers active support in the implementation of AI and BI scenarios so that the user becomes the master of their data. After all, the aim should always be not only to collect data, but also to use it through intelligent linking and evaluation mechanisms to drive the continuous improvement process (CIP) on the store floor in order to identify new efficiency potential.

COSCOM Computer GmbH

Anzinger Straße 5

85560 Ebersberg

Germany

https://www.coscom.de/

LEAD Industrie-Marketing GmbH

Herr André Geßner

+49 8022 91 53 188

+49 8022 91 53 189

agessner@lead-industrie-marketing.de

About COSCOM Computer GmbH:

COSCOM - Software, consulting and projects - for digitization in machining production

COSCOM is a leading software system house that standardizes, networks and optimizes production data in the machining industry. The connection between the ERP system and production is a top priority. Projects in tool management, tool and data management, CAD/CAM and machine simulation as well as Infopoint / DNC networking are realized around the CNC machine. Competence in consulting and target-oriented project management are the basis for joint success - one contact, one responsibility, one successful project!

The networking of COSCOM software products creates different, interface-free process solutions for the networking of all participants on the store floor. The main benefits for the user are a more efficient machining process with better product quality, greater adherence to deadlines and lower production costs. COSCOM offers everything from a single source - from software development, process consulting, sales and project management with implementation through to training/coaching, service and support.

COSCOM has been active on the market since 1978, making it one of the most experienced providers in the field of production automation and digitization in machining. Around 6,000 COSCOM solutions and around 25,000 machines and systems are currently networked with COSCOM systems throughout Europe. COSCOM as a partner means investment security, future security and innovation security for the customer.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Platform economy as the basis for business intelligence (BI) - software platform for AI and machine learning here

News-ID: 3466977 • Views: …

More Releases from COSCOM Computer GmbH

The COSCOM picking app for mobile use

The COSCOM ECO platform for controlling store floor processes in mechanical production has been enriched by another web app: The new COSCOM picking app, fully integrated in the COSCOM ECO system, ensures quick and easy work in central resource preparation. Warehouse bookings made easy: the "digital shopping list" saves time, reduces sources of error and enables parallel work on different orders. The system requirements are low, the app is extremely…

"Data provider" for automation systems with COSCOM and the store floor ECO syste …

Higher productivity, guaranteed delivery reliability and the right answer to the shortage of skilled workers - automation is also the first choice for CNC production. The COSCOM ECO system Connected Shopfloor brings together all the necessary production data centrally and makes object dependencies available at the point of action. The software platform also serves as a "data provider" and data repository for fully automated handling systems. As a result, fully…

More Releases for ECO

Eco Palm Leaf Plate Market Size, Status, Growth, current trend and forecast to 2 …

One of the world's leading market research firms, MarketInsightsReports is pleased to announce its new Eco Palm Leaf Plate Market report 2021-2027, covering all aspects of the market and providing up-to-date data on current trends.

The Eco Palm Leaf Plate Market report can help customers make business decisions and understand the strategies of major players in the industry. It provides an in-depth analysis of different attributes of industries such as market overview, growth analysis, historical…

Eco Palm Leaf Plate Market Size, Status, Growth, application, current trend and …

One of the world's leading market research firms, MarketInsightsReports is pleased to announce its new Eco Palm Leaf Plate Market report 2021-2027, covering all aspects of the market and providing up-to-date data on current trends.

The Eco Palm Leaf Plate Market report can help customers make business decisions and understand the strategies of major players in the industry. It provides an in-depth analysis of different attributes of industries such as market overview, growth analysis, historical…

'ECO-ST', World's first eco-friendly de-icer using a starfish

De-icer is a necessity during the winter, but it does cause great economic and environmental damage to our society including concrete damage, car corrosions, porthole, pets paw burns, and respiratory problems caused by dust. Various deicing products have been produced under the slogan 'eco-friendly', but they had functional limitations including reduced melting performance and caused other environmental problems, while the prices were high.

With an understanding of the limitations of the…

Eco Marine Power Expands Aquarius Eco Ship Project

Innovative low emission ship design project to be opened up to more technologies & companies

Eco Marine Power (EMP) unveiled today its plan to widen the scope of the Aquarius Eco ShipTM project and invite other companies to join this innovative low-emissions ship design initiative. As part of this plan a wider range of technologies will be studied including fuel cells, air lubrication systems & electrical propulsion plus ship owners that…

Paradu Tuscany Eco Resort

The Tuscany beach resort

Paradu Tuscany Eco Resort is a beach resort in Tuscany. It is located directly at the Mediterranean Sea. It stretches over an area of 36 hectares and offers everything a holiday destination needs. The sea and the beach were priced with the Blue Flag for its quality of water. Especially families and couples appreciate Paradu Tuscany Eco Resort. Guests arrive by car or by plane because Paradu…

Borneo Eco Tours

Kota Kinabalu, Sabah (openpr ) January 13, 2012 - Borneo is a beautiful tourist destination that preserves world's oldest rainforest and largest cave system, rare wildlife, unrevealed underwater marine life and more. Now, an expert eco-guide will reveal the mysterious behind the untouched beauty of Borneo.

"Borneo( http://www.borneoecotours.com/ ) is renowned for its untouched rainforest that is nearly 130 million years old and tagged as world's oldest rainforest. Borneo rainforest nurtures…