Press release

How The Use of IO-Link In The German Machinery Industry Will Develop Until 2016 Reveals The Quest Trend Magazine

Most machine-builders using IO-Link are really content with it. The use of IO-Link will boost until 2016. These are some results of the new Quest study, represented in the Quest Trend Magazine.In 2007 1% of the machine-builders used IO-Link and 13% at the end of 2013. By 2016 47% of the machine-builders intending to use IO-Link, i.e. nearly each second one! That means almost a triple increase in the next three years.

Also the use of IO-Link at the machines is to expand. The number of machines with IO-Link will grow more strongly than that of the machine production by 15% to 2016.

Finally the current users aim for the future to implement much more sensors with IO-Link per machine.

What is the security for the fact that IO-Link will win more users and will intensified be implemented at the machines in the future? It is the unified satisfaction the current users show with IO-Link.

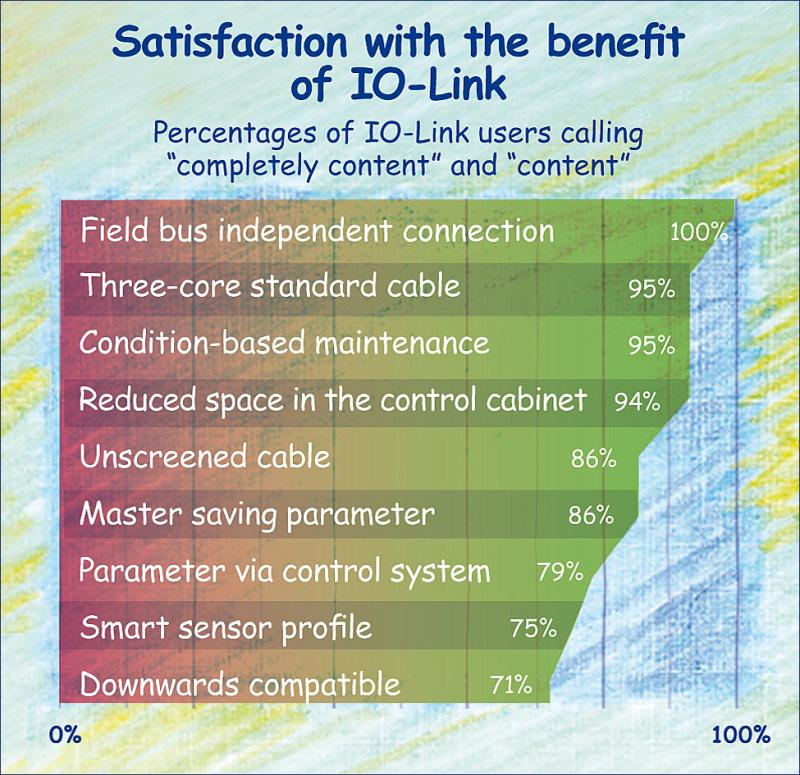

The possible benefit of IO-Link was comprehensively highlighted by nine aspects of use in the interviews.

More than 90% of the users are content with the four benefits „fieldbus-independent connection”, “three-core standard cable”, “condition-based maintenance and reduced control cabinet”.

More than 80% of the users are content with the benefit of the unscreened cable as well as with the feature that the IO link master stores the sensor parameters.

With the assigning of the sensor parameters through the control system, the sensor smart profile and IO-Link’s downward compatibility for binary sensors over 70% of the users are satisfied.

Furthermore 13% of the users completed cost savings through IO-Link. So a machine tool builder detected on his own cost savings by 30%:

„The first crucial point is the reduction of the installation expenses, combined with cost reduction. We estimate the cost reduction with 30%. These 30% are a mix for more expensive hardware, reduced installation costs and saving regarding the coworkers’ work times. On the one hand the cost saving is not always immediately apparent for a procurement manager as he is only looking at the prices. At first all field bus systems are more expensive than the discrete wiring. On the other hand just the mix of work time for installation and startup together with the material costs reduces total costs to 30%.“

„Less wiring effort, less interference sources, cost savings“ – this statement, based on his experiences, provided a machine-builder producing textile machines. These benefits are at the same time those three benefits users of IO-Link concentrated three quarters of their benefit denominations.

Quest TechnoMarketing interviewed nearly 200 companies, i.e. 30% of the machine-builders in 10 important sectors of the machinery industry with 100 and more employees. This relatively high portion provides representative results having been concentrated to detailed trends for the future until 2016 on 80 pages.

The article in the Quest Trend Magazine about IO-Link is available on http://www.quest-trendmagazine.com/en/machinery-industry/automation/sensors/io-link-in-the-machinery-industry-until-2016.html.

About Quest Trend Magazine:

Quest Trend Magazine publishes trends in automation from the users's point of view mainly in machinery industry, automotive and F&B industry. The economic backdrop of these trends is highlighted as well.

The trends in automation technology are based on market surveys by Quest TechnoMarketing. The economic backdrop is analyzed by Quest Research, a department of Quest TechnoMarketing.

About Quest TechnoMarketing:

Quest TechnoMarketing, Bochum, London, is specialized in market surveys and marketing for the automation technology for more than 20 years and the publisher of the Quest Trend Magazine.

Thomas Quest

Quest Trend Magazine

Dibergstr. 64

44789 Bochum, Germany

Phone +49 234-34777

Fax +49 234-33 22 02

Email: media@quest-trendmagazine.com

Internet: http://www.quest-trendmagazine.com

Quest TechnoMarketing

Thomas Quest

Dibergstr. 64

44789 Bochum, Germany

Phone +49 234-34777

Fax +49 234-33 22 02

Email: media@quest-technomarketing.com

Internet: http://www.quest-technomarketing.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How The Use of IO-Link In The German Machinery Industry Will Develop Until 2016 Reveals The Quest Trend Magazine here

News-ID: 293359 • Views: …

More Releases from Quest Trend Magazine

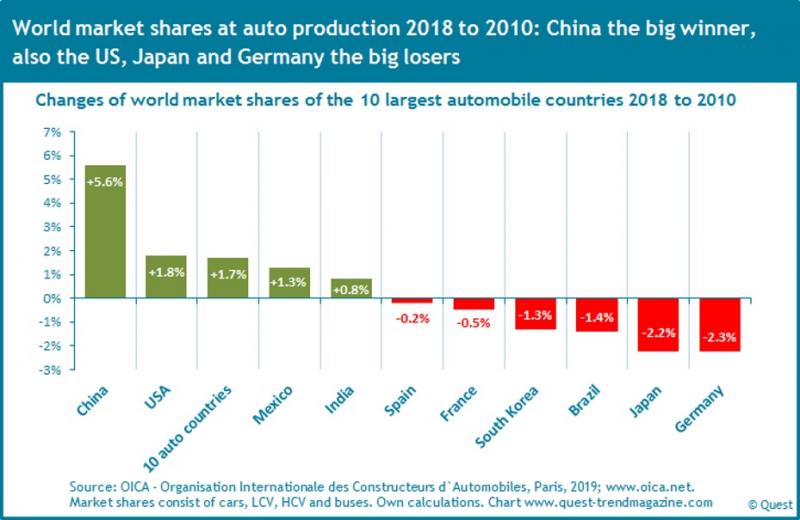

China, the USA increase market share in world car production, Japan, Germany los …

The new Quest Trend Report establishes the ranking of the world market shares of the automotive countries and lists their market shares for 2018 and in comparison to 2010.

In the ranking of the ten largest automotive countries in the period from 2010 to 2018, only first place, China, and tenth place, France, remained unchanged. The eight other automotive countries changed their position among the ten largest automotive countries.

The world's…

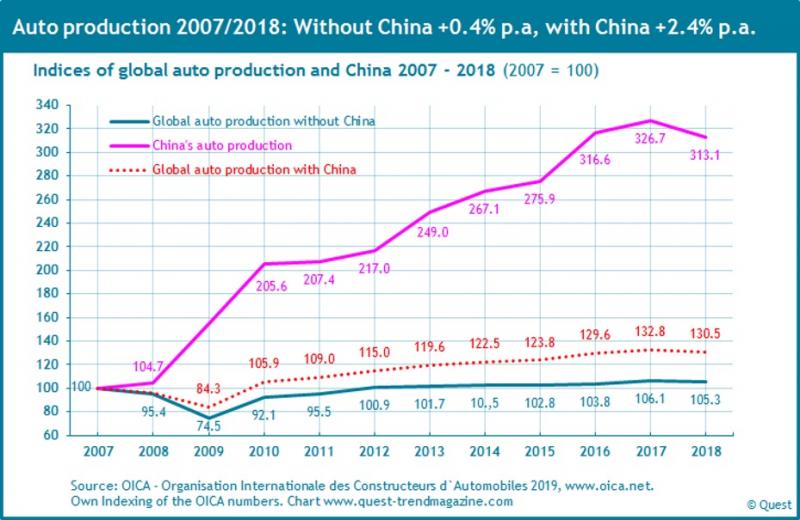

Global automobile production has been stagnating since the global economic crisi …

The new Quest Trend Report analyzes global auto production since the global economic crisis of 2007 to 2018 and the contribution of China and its market share to global auto production.

World car production plunged to its crisis low in 2009. But one year later it had not only left this crisis low behind it, it had even surpassed its pre-crisis level! The jump in world car production was not primarily…

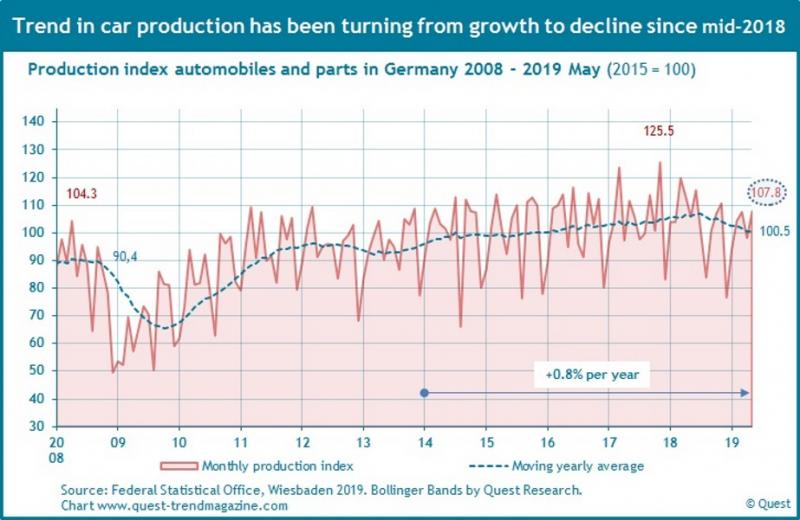

Automobile production in Germany: Trend change from growth to decline – new Qu …

The change in trend has been taking place in the German automotive industry since mid-2018, as the updated economic report in the Quest Trend Magazine shows.

The monthly updated economic report covers the period from 2008 to 2019 May. The trend in production and sales in the German automotive industry is methodically determined as the average of the last twelve months.

The trend in automobile production in Germany surpassed its pre-crisis…

Germany's industrial production growing at 2% p.a., stagnation likely for 2019

The new Quest Economic Report examines the trend growth of industrial production in Germany and combines the current situation with a trend forecast.

The new Quest Economic Report examines the trend growth of industrial production in Germany. The trend is defined as the moving average of the last 12 months. The report divides the trend in industrial production into two phases since 2008.

Only at the end of 2015 the trend…

More Releases for TechnoMarketing

Latest Feedback of the German Machinery Industry on Industry 4.0 - New Report in …

Along the market survey from Quest TechnoMarketing about the engineering of the machine automation until 2017 the machine-builders also assessed “what Industry 4.0 is supposed to mean for the engineering of the machine until 2017”.

80% of the investigated machine-builders in the ten sectors of the German machinery industry provided their feedback to this question. The following numbers refer to these machine-builders.

The open question without further specifications invited to a…

Electric linear actuators have been growing for 10 years

Bochum, July 14, 2010. During the last 10 years from 2001 to 2010 the use of electric linear actuators in the German machinery industry has increased fivefold.

So the portion of the machine-builders using electric linear actuators at the machines increased from 3,5% to 19%.

Linear actuators produce a straight-line resp. translational motion. So e.g. the hot glue nozzle of a packaging machine can be guided straight-lined across a paper…

RFID - constantly and throughout the machinery industry implemented

Bochum, July 5, 2010. This year 14% of the machine-builders intend to implement RFID at the machines.

RFID stands for radio frequency identification and provides the wireless identification of goods, semi-manufactures or workpieces in the industrial sector.

Last year 15% of the machine-builders wanted to implement RFID at the machines. So RFID shows a constant implementation during the last two years.

This implementation is taking place with all or almost all of…

Intensified interest in application-optimised I/O modules

Bochum, June 15, 2010. The machine-builders are intensified interested in application-optimised I/O modules this year. This confirms the trend to fine-tuning the control and drive technologies that determines the changes in the automation technology this year.

With 11% each tenth machine-builders intend to change to application-optimised I/O modules this year. That is an increase in relation to the previous year by more than one third as this value was 8%.

What application-optimised…

Panel PC benefits from the current trend to fine-tuning the control technology

Bochum, 7th June 2010. Machine-builders prefer fine-tuning the control technology this year. This means to improve the consisting control technology at the machines instead of changing the control technology. The Panel PC benefits from this current trend.

Panel PC means operator panel with integrated control system. Compared with other control technologies such as PLC, PC, microprocessor control, CNC or contactor-based control technology the Panel PC shows the highest portion with new…

The trends in the automation - start of the serial „automation, supplier struc …

Bochum, May 25, 2010. The Quest Trend Magazine has recently published the first part of a three-part series of articles to the topic „automation, supplier structure, economic crisis“. It concerns the connection between automation technology, its suppliers and the economic crisis.

By now two main trends in the automation technology have been appearing. The first main trend of the automation substituted the electro-mechanics by microelectronics. The second main trend consists of…