Press release

Follow-up order for carton-, flat sorting

VITRONIC supplies over 2,000 Auto-ID camera systems to parcel and post customerVITRONIC Machine Vision LTD is proud to announce it has been awarded a multi-million dollar contract to automate the manual processing of flats and small parcels from a large parcel and post customer.

Under the terms of the contract, VITRONIC Machine Vision LTD, will provide over 2,000 VICAMsnap! camera units to be deployed in early 2014 for their facilities throughout the United States. This will bring VITRONIC's fielded units for this customer to 3,000 units for this program.

The camera systems will provide scanning and barcode decoding for all customer specific linear and 2-dimensional codes (PostNet™, Planet Code®, Datamatrix, PDF-417 and Intelligent Mail® Barcodes), provide image capture and archiving routines, and allow the customer to provide additional tracking capabilities throughout their network. The VITRONIC VICAMsnap! solution replaces a previous multi-step process and will allow faster manual sorting and throughput efficiency along with providing improved tracking visibility enhancing the customer experience.

“We are pleased to continue our relationship and this program continuation is a direct result of a successful roll out in 2013 and is based on the performance, ease of installation and in the overall improvements in operational efficiencies. Our solution allows our customers to take advantage of the latest innovative technology in the market today. There is no product like the VICAMsnap! in the market today and we are proud of our successes", stated Michael Schindler, VITRONIC Machine Vision LTD’s president of North American operations.

The VITRONIC VICAMsnap! is a compact, lightweight camera-based solution that packs performance into a robust design. It is equipped with white illumination which allows for the reading and decoding of colored barcodes and provides more effective reading of damaged or poorly printed barcodes on colored backgrounds. The VITRONIC VICAMsnap! provides a 12x10 inch width of field and 16 inch depth of field (read area 310mm x 260mm x 300mm) to allow operators to immediately capture all 1D and 2D barcodes present on parcels, flats and boxes.

A target illumination on the package allows the operator to quickly find the scan zone and process the items being scanned. The VICAMsnap!provides immediate feedback to the operator through audible tones and configurable voice commands. It features visual red and green go/no go LED flash indicators directly on the items being scanned, allowing the operator to process the item even in noisy industrial environments. This innovative approach with audible and visual operator feedback also provides 508 compliance features. The system is equipped with a powerful processing unit that provides more than just barcode reading; it allows image capture/archiving and complex processing routines completed in real time. Images can be compressed, binarized, pre-processed for OCR and transmitted via Gigabit Ethernet to a host server for further processing or offline archiving purposes.

The VICAMsnap! camera is an advanced information and image acquisition system designed for manual and automated pro-cessing in the material handling, warehousing, parcel/post, distribution and manufacturing industries.

For more information about this product and its capabilities, please email Jay Stone at jay.stone@vitronic.com or watch a vid-eo on our Youtube channel at http://www.youtube.com/watch?v=rzflxyWDqIY

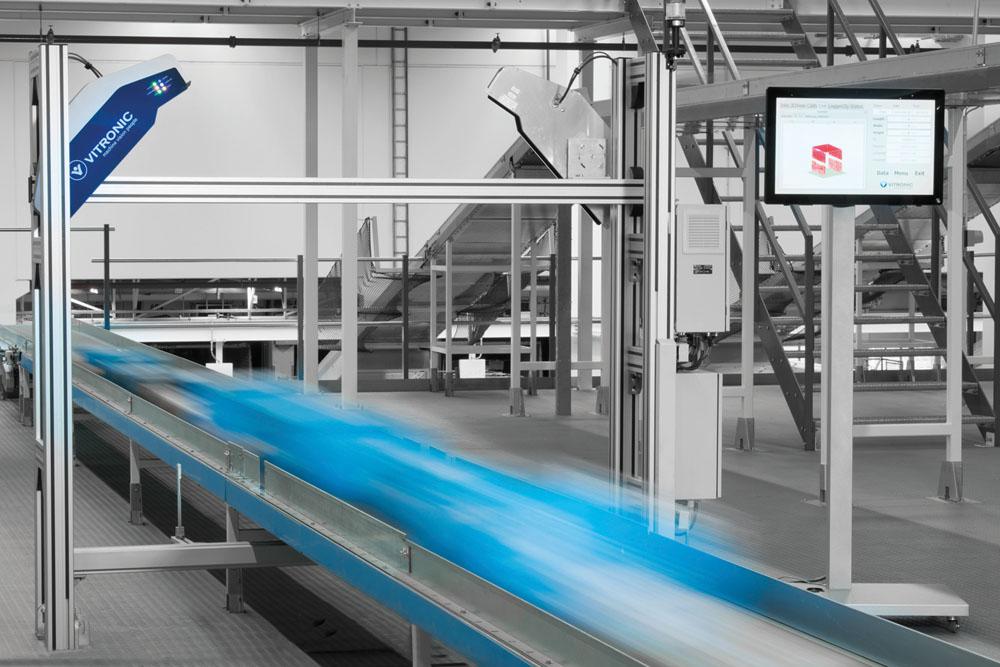

VITRONIC Machine Vision Ltd, a subsidiary of VITRONIC GmbH in Germany, is located in Louisville, KY. VITRONIC are international leaders in the packaging vision technology market. VITRONIC specializes in providing advanced technological solutions to a broad range of markets, such as logistics, traffic technology, and industrial automation. Its products incorporate the latest in machine vision equipment and software to resolve a wide range of issues. In a busy warehouse or post depot, maintaining control of what parcels are going in and out is essential, VIPAC is VITRONIC’s answer. It comprises a system that utilizes extensive image processing, to provide a state-of-the-art solution for multi-sided object identification. Offering a unrivaled read rate and much faster than conventional technologies, it makes parcel tracking easy.

Birgit Löschner

Tel: +49 (0)611 – 7152 - 261

birgit.loeschner@vitronic.com

VITRONIC Dr.-Ing. Stein

Bildverarbeitungssysteme GmbH

Hasengartenstr. 14

65189 Wiesbaden, Germany

Tel: +49 (0)611 – 7152 - 0

Fax: +49 (0)611 – 7152 - 133

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Follow-up order for carton-, flat sorting here

News-ID: 277450 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Fast …

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all…

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…

More Releases for VICAMsnap!

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…

Action! The compact multi-code reader VICAMsnap! on video

Action! The compact multi-code reader VITRONIC VICAMsnap! on video

Camera systems for capturing items within the scope of material flow management, ware-housing and parcel/post services in both the retail trade and the production industry help reduce throughput times, accel-erate business processes and lower costs. The latest VITRONIC video demonstrates countless opportunities for using the VICAMsnap! multi-code reader and highlights the system’s advantages.

VICAMsnap! is a camera-based data capture solution that combines a…

VITRONIC at Smart Conference and Expo 2013 in Australia

For efficient sorting, order picking and storage of goods, customer and object related data needs to be captured and processed. VITRONIC will present its camera-based identification systems for Parcel Logistics and Warehouse & Distribution companies at Australia’s leading supply chain event Smart Conference and Expo in Sydney: VICAMsnap! speeds up capture processes, increases productivity of employees and reduces the logistics cost per item.

Advantages for efficiency, productivity and cost-savings

The compact…

VITRONIC supplies over 1,000 Auto-ID systems to parcel and post customer

VITRONIC Machine Vision Ltd. is proud to announce it has been awarded a multi-million dollar contract to automate the manual processing of flats and small parcels from a large parcel and post customer.

Under the terms of the contract, VITRONIC Machine Vision Ltd. will provide over 1,000 VICAMsnap! camera units to be deployed in early 2013 for the customer’s facilities throughout the United States. The VITRONIC camera systems will provide scanning…

VITRONIC at ProMAT 2013

Camera systems speed up processes and reduce expenses for data capture of Parcel Logistics and Warehouse & Distribution

For efficient sorting, order picking and storing of goods, customer- and object-related data needs to be captured and processed. At the ProMAT tradeshow in Chicago, VITRONIC will be presenting state-of-the-art camera systems for Parcel Logistics and Warehouse & Distribution companies: VICAMsnap! and VICAMssi2 speed up capture processes, increase productivity of employees and reduce…

VITRONIC at Post-Expo in Stuttgart 2011

Camera-based Auto-ID systems for highest read rates and more efficiency

Wiesbaden, 25th July 2011 – At Post-Expo in Stuttgart from 27th to 29th September 2011, VITRONIC will be presenting high-capacity camera-based systems for the identification of packages.

VITRONIC’s Auto-ID systems recognize, analyze and evaluate all relevant information from barcodes, 2-D codes and characters (OCR) - also many different code types in one image (multi-code reading). Furthermore, important additional information such as the…