Press release

Quick and economical waterjet cutting with ABRALINE Advanced

The AMS Abrasive Management System with cutting head, abrasive metering system and ABRALINE Advanced

The abrasive bulk transfer system ABRALINE for waterjet cutting machines consists of an abrasive silo and a smaller pressure vessel directly beneath it. With the help of pressurized air, the vessel conveys abrasive sand to the waterjet cutting heads via a hose. At the outlet hopper of the pressure vessel, a sensor monitors the fill level of the abrasive. As soon as the abrasive runs low, a signal of the sensor causes a time-controlled opening of the inlet valve which replenishes the tank thus providing a continuous abrasive flow to the waterjet cutting heads.

Enhancement of a successful system

For some years, KMT has been successfully selling the ABRALINE system in the market. Now, the company has extended the product line by a model which has been designed especially for waterjet cutting machines operating at full capacity: The model ABRALINE Advanced features an extremely large abrasive silo. Therefore, a single abrasive load lasts more than twice as long as a single load of the smaller version of the transfer system. The silo has been dimensioned to be able to hold a complete abrasive sand standard packaging unit of 1 t. This fact does not only lead to longer continuous operation times of the connected waterjet cutting machines but also to a time-saving and simple filling process of the silo as the necessity for an intermediate storage of the abrasive is eliminated.

ABRALINE Advanced convinces with its optimized design

Moreover, the model ABRALINE Advanced is very maintenance-friendly and reliable: Instead of using a usual cone seal, the abrasive silo and the pressure vessel are connected by a pneumatic pinch valve. A free production flow, minimum frictional resistance and the absence of leaks and clogging are some features of such a valve which allow for long lifetimes even at continuous operation. Furthermore, the opening and closing of the pinch valve require a lower air volume compared to the cone seal. As a consequence, the necessary maximum level of air pressure decreases significantly.

Solutions for different waterjet cutting applications

With the two model types, KMT offers a solution for different requirements concerning waterjet cutting systems. The smaller version ABRALINE Comfort is sufficient for ensuring the abrasive feed for occasional cutting needs. For larger waterjet cutting machines which operate continuously and with multiple waterjet cutting heads, machine operators should consider using the model ABRALINE Advanced.

About KMT Waterjet Systems

KMT Waterjet Systems is a leading multinational manufacturer of components for waterjet cutting systems. The company develops solutions for a wide range of industries and applications. Since 1971 the company has been dedicated to long-term customer relationships. Continuous investment in innovation has made KMT Waterjet Systems the market leader in the waterjet cutting industry. High pressure pumps, cutting heads, abrasive systems, high pressure tubes, original spare parts and a global service network are among the key products and services of the company.

KMT GmbH

Ralf kleine Brörmann

Hohe Strasse 4-6

61231 Bad Nauheim

Germany

Phone: +49 (0) 6032 / 997-126

Fax: +49 (0) 6032 / 997-270

E-Mail: ralf.broermann@kmt-waterjet.com

Internet: www.kmt-waterjet.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Quick and economical waterjet cutting with ABRALINE Advanced here

News-ID: 251291 • Views: …

More Releases from KMT Waterjet Systems

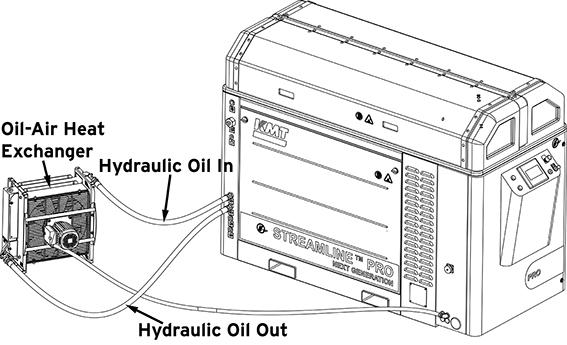

Everybody be cool – A Comparison of Cooling Systems for High Pressure Pumps

Which cooling system fits best for which high pressure pump installation for waterjet cutting? When operating a high pressure pump for waterjet cutting, it is crucial to run a reliable cooling system as some vital components of the pump may be damaged if the temperature of the hydraulic oil rises above a certain point. Therefore, KMT Waterjet high pressure pumps carry out an automatic shut-down as soon as the oil…

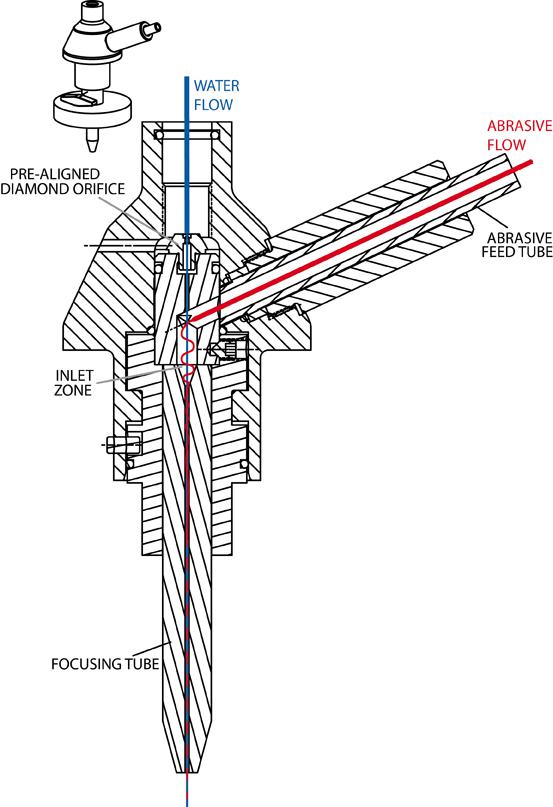

Focus on Abrasive Cutting

In the process of abrasive waterjet cutting, the focusing tube is a vital component. After all it is in this tube where high pressure water and abrasive are focused to an efficient cutting jet. During this procedure, the physical processes in the tube crucially affect the final speed and precision of the cutting jet as well as the kerf width at the workpiece. However, which factors influence the functionality of…