Press release

Let’s Talk About… How long plasma treatment lasts?

The most commonly asked question concerning plasma surface treatment is; How long does plasma treatment last?In this ‘Let’s talk About…’ article we discuss the main factors that influence the lifetime of plasma surface treatments and explain how these factors can affect different materials.

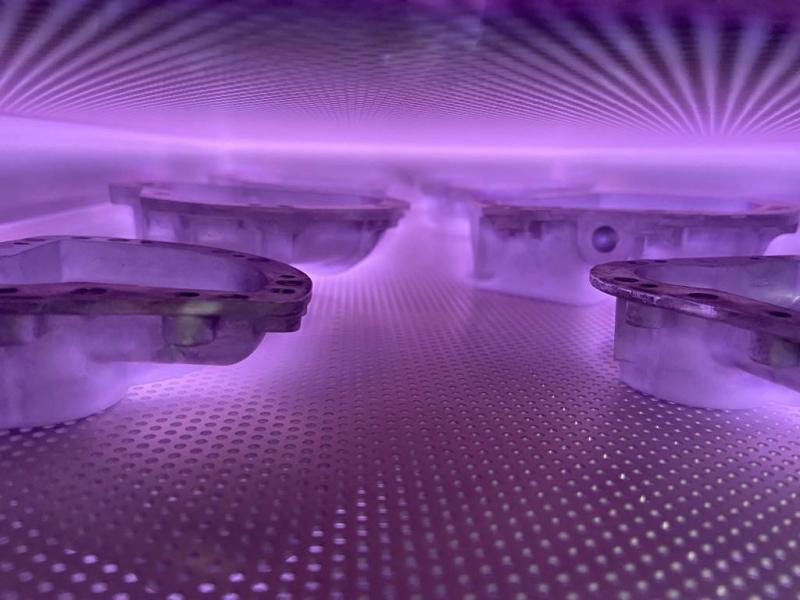

Plasma surface treatment is an established and effective method of improving the adhesion characteristics of a wide range of materials. Even for the most challenging polymers such as PET, PPS, PEEK, PTFE, acetals (POM), polyamides and polyolefins, plasma treatment is a fast and reliable process to increase the surface energy of a material, thereby making it easily wettable.

Wettability refers to the ability of ink, paint or adhesive to spread on a surface and form intimate contact and strong chemical bonds with surface molecules. Most polymers are naturally hydrophobic, meaning that liquids bead up on the surface and do not form the large numbers of strong bonds which are a pre-requisite for good adhesion. Metals, glass and ceramics by contrast are naturally hydrophilic, however surface contamination is often present from the machining/production processes which impede adhesion to these materials also. Surface contamination may also be present on many engineering polymers in the form of e.g. mould release agents, plasticizers, pigments and antioxidants.

Plasma surface treatment works by a two-fold action; (i) removal of contamination from the surface (cleaning) and (ii) increasing the surface energy by the attachment of oxygen-containing molecules (activation). Cleaning takes place on all surfaces whereas activation tends to apply mainly to polymers.

What causes Plasma Treatments to decay?

In the case of plasma cleaning, parts will tend to remain in a cleaned state indefinitely as long as they are stored under clean conditions and are free from atmospheric contaminants or from the transfer of oils and salts by e.g. touching with bare skin.

The situation is a little more complex in the case of polymers. The cleanliness factors above still apply but surface activation is now dominant in increasing the surface energy of the material. The reduction in the effectiveness of plasma treatment over time, i.e. the reduction in surface energy, is known technically as hydrophobic recovery. The bulk properties of a plasma-treated material remain unchanged in comparison to the surface and over time the molecules from within the bulk may migrate to the surface through thermodynamically driven reorientation, causing the oxygen-containing polar groups to be relocated underneath the surface.

This recovery is to a large extent a characteristic of the material rather than the plasma treatment and we will discuss some reasons for this below.

Type of material

The characteristics of the material undergoing plasma treatment are one of the most important factors that affect the rate of hydrophobic recovery. Some polymers are more tightly packed, and the sub-surface molecules have less freedom of movement, hindering their ability to relocate to the surface and thus slowing down the recovery process. Conversely, lower density polymers can more easily reorientate and the oxygen-containing surface molecules will in turn migrate into the bulk. Low molecular weight additives such as plasticizers and pigments will, if present, also migrate back to the surface over time.

Figure 1 (available on the website) demonstrates this difference by comparing the hydrophobic recovery of low-density polyethene (LDPE) and high-density polyethylene (HDPE). LDPE recovers to a lower energy state (higher water contact angle) than HDPE, although both materials retain a higher surface energy than the untreated materials, even after several weeks.

There are many other intrinsic properties of a polymer that may have an effect on the rate of recovery, such as crystallinity, polarity, conductivity etc.

Figure 2 (available on the website) demonstrates the differences between three different polymers after undergoing the same plasma treatment and being stored under the same conditions. It can be seen that, not only is the rate of recovery different, but some polymers are treated much more effectively than others, with polystyrene (PS) remaining in a high state of activation even after several weeks.

Once again, it can also be seen that all of the materials remain in an activated state and never fully recover to the untreated low energy state level.

Duration of plasma treatment

There is some evidence that a longer exposure time to plasma may result in a higher number of surface and subsurface bonds of the material being broken by UV radiation from the plasma, leading to easier chain motion of molecules in the bulk of the material and hence a more rapid recovery process. Some research even states that plasma times of just 5 seconds are sufficient. Such short times however are not always enough for the first step removal of contamination and it’s therefore important to strike a balance.

Figure 3 (available on the website) shows the surface energy recovery behaviour of plasma treated PET for different plasma treatment times. Although the rate of recovery is faster for longer plasma treatment, this is still the most effective treatment time overall and results in a lower contact angle (higher surface energy) overall.

Storage conditions of plasma-treated materials can have a large effect on the energy state of the surface. Higher temperatures can lead to faster hydrophobic recovery due to the increased ease of mobility of chain structures beneath the surface for example.

Figure 4 (available on the website) shows the effect of storage temperature on a water contact angle of plasma-treated PET. It can be seen that higher temperature storage conditions contribute to the rapid recovery of the sample. In this example, water contact angle results show that the surface energy returns to almost 90% of its previous value in less than one hour.

Airborne contamination and the transfer of oil and salts from contact with bare hands also have a detrimental effect on surface energy.

Covering the plasma-treated material will prevent recontamination but care must be taken that the covering itself does not transfer or leech contamination. Figure 5 (available on the website) compares two samples following plasma treatment; one that has been covered and one that has been left uncovered. The uncovered parts display an enormous variation in contact angle over time, probably due to different types and degrees of contamination on different parts of the surface, whereas the covered samples show a more stable expected recovery over time.

Type of plasma treatment

Another factor that can affect the rate of recovery of a plasma-treated material is the nature of the gas used in the plasma process. Different gases can introduce different functional groups onto the surface, which in turn leads to slightly different surface characteristics.

Figure 6 (available on the website) compares the measured water contact angle of plasma-treated PET for different process gases. The oxygen treated PET sample retained the lowest contact angle, although air showed the highest initial decrease. Air plasma processes are often perfectly suitable for treating materials due to the oxygen content within ambient air and also offer a cost-saving compared to using bottled gas.

Example Water Contact Angles

The following images (available on the website) show the change in water contact angle over time for a plasma-treated sample. Complete wetting of the sample can be seen immediately following plasma treatment, indicating high surface energy and excellent adhesion characteristics. The water contact angle increases over a 7-hr period as the sample slowly recovers, but always remains in a higher surface energy state than the untreated sample.

Conclusions

Each material must be considered individually when questioning how long a specific plasma treatment will last, although overall, most polymers will retain a higher surface energy than the untreated polymer for several weeks.

In general, for the best results, it is better to perform printing/bonding processes as soon as is practically possible following plasma treatment, however, if that isn’t possible then it is worth considering the following:

- Covering the parts if possible, using foil, not leaving the treated surface open to ambient air.

- Always using powder-free gloves to handle plasma-treated parts.

- Storing plasma-treated parts in as cool an area as possible, avoiding warm areas.

- Reducing long treatment times. Oxygen plasma is capable of fully cleaning and activating a polymer surface within a few minutes.

Henniker have an extensively equipped plasma processing and testing laboratory in our UK headquarters where we can conduct trials to determine both the effectiveness and lifetime of plasma treatment on a wide range of samples.

Please contact us today if you would like to learn more.

www.plasmatreatment.co.uk

The original article can be viewed here: https://plasmatreatment.co.uk/knowledge-base/knowledge-articles/142-let-s-talk-about-how-long-plasma-treatment-lasts

UK Headquarters

Henniker Plasma

3 Berkeley Court

Manor Park

Runcorn, WA7 1TQ

Tel: +44(0)1925 830 771

Fax: +44(0)1925 800 035

Email: info@plasmatreatment.co.uk

Press contact

gbolton@plasmatreatment.co.uk

Henniker - Passionate about Plasma®

We are the leading UK manufacturer of plasma treatment equipment & processes, from small, low-cost bench-top plasma systems to high throughput production scale equipment for cleaning, activation and coating.

Plasma surface treatment is capable of producing unique properties over the entire surface of any material that is processed. Material properties are greatly enhanced, adding significant functional and commercial value to a product and/or replacing other costly and inefficient process steps. Plasma treatments take just minutes and there are no harmful waste products.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Let’s Talk About… How long plasma treatment lasts? here

News-ID: 2211488 • Views: …

More Releases from Henniker Plasma

Reducing Adhesion Failures in the Automotive Industry

Plasma pre-treatment is a crucial step for improving the quality and durability of automotive assemblies and components. It enhances the adhesion and compatibility of different materials that are used for encapsulation, printing, or painting processes. By applying plasma to the surface of low-energy materials, it removes contaminants and creates functional groups that increase the surface energy and reactivity. This results in a stronger and more uniform bond between the materials,…

Plasma Treatment of Fluoropolymers

Henniker Plasma, a leading manufacturer of plasma surface treatment equipment, presents Plasma Treatment of Fluoropolymers

PTFE, and other fluorinated polymers, are chemically inert, thermally stable and highly hydrophobic, due to their intrinsically low surface energy. The chemical inertness of PTFE as an example, means that it is virtually impossible to form lasting adhesive bonds and coatings tend instead to form droplets and 3D particles on the surface rather than a uniform…

New online Materials Library for Plasma Surface Modification

Materials science is at the forefront of many of today's technological advancements in areas such as medical device fabrication, filtration, aerospace, and semiconductor processing, to name but a few. Plasma treatment has long been recognised as being able to transform the surface properties of a wide range of materials, without affecting the bulk properties in any way, adding significant functional and commercial value to a product and/or replacing costly or…

More Releases for Figure

Floralite - Reduce Fat & Get Attractive Figure How To Buy!

Floralite Have you been working on your eating routine without seeing the results that you are anticipating? There is indeed thing called Floralite diet pills.

Advantages of Floralite

Floralite One of various things to esteem about this thing is that it's made expressly for the Floralite diet. That is an epic notwithstanding considering the way that when you use a thing that is custom fitted to work with the movements…

THE WORLD'S MOST CONTROVERSIAL ACTION FIGURE...EVER!

FOR IMMEDIATE RELEASE

THE WORLD'S MOST CONTROVERSIAL ACTION FIGURE...EVER!

Contact: William Hirsch - Schlock Toys @ +1-949-677-9353 or DocSchlock@SchlockToys.com

Featured on Tomi with Fox News host Tomi Lahren! SCHLOCK TOYS join forces with Kickstarter to Make Toys Great Again!

The Kickstarter campaign page can be found HERE: https://www.kickstarter.com/projects/schlocktoys/collectors-edition-talking-trump-2020-man-of-action-figure/description

“What a great message to be sent, and I think Trump himself would love this and that he’d be excited about it!”

- Tomi Lahren, Fox News

“You…

Macarons Market Latest Sales Figure Signals More Opportunities Ahead

Global Macarons Sales Market(Sales,Revenue and competitors Analysis of Major Market)from 2014-2026 is latest research study released by HTF MI evaluating the market, highlighting opportunities, risk side analysis, and leveraged with strategic and tactical decision-making support. The study provides information on market trends and development, drivers, capacities, technologies, and on the changing investment structure of the Global Macarons Market. Some of the key players profiled in the study are La Dure�,…

Global Womens Figure Skates Market Growth 2019-2024

LP INFORMATION offers a latest published report on Womens Figure Skates Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Womens Figure Skates market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019.…

Figure Skating Equipment Market Report 2018: Segmentation by Type (Figure Skate …

Global Figure Skating Equipment market research report provides company profile for SP-Teri, Graf Skate, Riedell Shoes, Roces, American Athletic, Rollerblade, Winnwell, Dongguan King Line, Jackson Ultima, HD Sports(MK Blades, John Wilson), Edea, Risport Skates, Paramount Skates and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY…

Long-lasting Performance Improvement with Key Figure Analysis

Vienna/Reutlingen, October 17, 2012 – Manz, a leading high-tech mechanical engineering company, is optimizing its processes in strategic sourcing in order to recognize the risks and potential associated with each supplier early on so that the sourcing department can react to them in time. POOL4TOOL’s customized eSolutions localize and analyze key figures that are relevant to the decision making process, and displays these figures in a comprehensive and transparent way.…