Press release

SABIC Innovative Plastics Teams with IAV GmbH to Develop Electric and Hybrid Vehicle Powertrain Solutions with High-Performance, Lightweight Thermoplastics

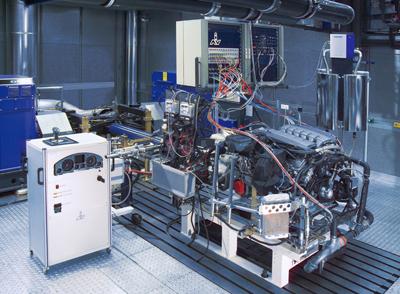

BERGEN OP ZOOM, The Netherlands – April 6, 2011 – Here at the VDI conference – Booth #74 – SABIC Innovative Plastics today announced its collaboration with IAV GmbH, a world leader in advanced vehicle and powertrain systems, to develop advanced thermoplastic solutions that can replace metal in electric vehicle (EV) and hybrid powertrain components. Specifically, the two companies are targeting new ways to optimize vehicle performance and efficiency, including lightweighting to offset heavy battery packs and shielding in areas of high voltage.“Our strategic collaboration with IAV is all about creating innovative new options for our customers as they strive to develop and deliver a range of electrified vehicles to consumers, whether it’s hybrids, plug-in hybrids or pure battery electrics,” said Gregory A. Adams, vice president, Automotive, SABIC Innovative Plastics. “Bringing together complementary skills and strengths from different companies is increasingly the key to delivering the rapid technological advances that our customers worldwide want and deserve. We see a winning combination with IAV’s leading expertise in advanced powertrain engineering and our selection of tough, high-performing specialty materials and application development know-how. We look forward to helping automakers develop next generation powertrains and powertrain components as a result of this collaboration.”

IAV has been developing innovative concepts and technologies for future vehicle generations for 27 years. In the area of e-mobility, the company develops powertrains, control units, on board systems, high voltage battery systems and other systems and components for battery and hybrid electric vehicles.

“We are pleased to be working closely with SABIC Innovative Plastics on new powertrain components that will take full advantage of the light weight, shielding performance, corrosion and high temperature resistance of thermoplastic resins and compounds,” said Kurt Blumenröder, president and CEO, IAV GmbH. “SABIC Innovative Plastics’ extensive experience in metal replacement and high performance engineering thermoplastics is a great fit with our engineering expertise. We anticipate important advancements that can help the automotive industry make significant progress in the performance and efficiency of hybrids and electric vehicles.”

Thermoplastics Target Weight, Temperature, Shielding Challenges

To sustain the full environmental advantages of hybrid, plug-in hybrid, and battery electric vehicles, the additional weight of battery packs – up to 300 kg (approx. 661 lbs.) on a mid-sized car – needs to be offset by weight reduction in other areas. Thermoplastics including Noryl* polyphenylene oxide (PPO) and Valox* polybutylene terephthalate (PBT) resins from SABIC Innovative Plastics can replace steel in battery frames and housings. These resins also offer chemical and temperature resistance, dimensional stability and flame retardance.

The increasing use of lithium ion and lithium polymer batteries, which have higher power and energy density, requires thermal management solutions for battery packs. These batteries operate best at room temperature. To control temperature, liquid cooling often replaces air cooling for greater efficiency. As a result, these liquids require chemically resistant, high-performance engineering thermoplastic materials. Further, if power is withdrawn from a battery, it will heat up – thus requiring materials with excellent temperature resistance. SABIC Innovative Plastics’ Ultem* polyetherimide (PEI) resins deliver high heat resistance and inherent flame retardance, and Valox PBT resins provide high heat and chemical resistance.

In hybrid-electric vehicles, the higher the voltage, the more important electromagnetic interference/radio frequency interference (EMI/RFI) shielding becomes to control the potential disturbance from the different electronic components such as inverters, electronic control units and battery management system. LNP* Faradex* compounds from

SABIC Innovative Plastics provide exceptional EMI/RFI shielding properties without the heavy weight of metal layers or metallization.

Compared to internal combustion engines that supply heat to the vehicle’s interior, alternative energy vehicles rely on battery power for heating and air conditioning, making insulation more vital to avoid a heavy drain on the battery. Lexan* polycarbonate glazing solutions offer five times the insulative performance of glass, and specialized infrared (IR) absorbing grades of Lexan resin can further optimize air conditioning by reducing the amount of heat load transferred to a vehicle’s interior in hot climates or sunny weather.

For additional information on SABIC Innovative Plastics’ thermoplastic materials, please go to www.sabic-ip.com. For technical product inquiries, please contact us at www.sabic-ip.com/prtechinquiry.

About SABIC Innovative Plastics

SABIC Innovative Plastics is a leading, global supplier of engineering thermoplastics with a 75-year history of breakthrough solutions that solve its customers’ most pressing challenges. Today, SABIC Innovative Plastics is a multi-billion-dollar company with operations in more than 35 countries and approximately 9,000 employees worldwide. The company continues to lead the plastics industry with customer collaboration and continued investments in new polymer technologies, global application development, process technologies, and environmentally responsible solutions that serve diverse markets such as automotive, electronics, building & construction, transportation, and healthcare. The company’s extensive product portfolio includes thermoplastic resins, coatings, specialty compounds, film, and sheet. SABIC Innovative Plastics (www.sabic-ip.com) is a wholly owned subsidiary of Saudi Basic Industries Corporation (SABIC).

About Saudi Basic Industries Corporation

Saudi Basic Industries Corporation (SABIC) ranks among the world’s top petrochemical companies, and is a global market leader in the production of polyethylene, polypropylene, advanced thermoplastics, glycols, methanol and fertilizers. SABIC manufactures with a global footprint in Saudi Arabia, the Americas, Europe and Asia Pacific. The company operates in more than 40 countries across the world with 33,000 employees worldwide. It has significant research resources with 18 dedicated Technology & Innovation facilities in Saudi Arabia, the USA, the Netherlands, Spain, India and China. SABIC recorded a net income of SR 21.59 billion(US$ 5.73 billion) in 2010, and sales revenues totaled SR 152 billion (US$ 40.5 billion).

# # #

* Trademarks of SABIC Innovative Plastics IP B.V.

Marketing Solutions

Kevin Noels

Box 6

2950

Kapellen

Belgium

0031164317011

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SABIC Innovative Plastics Teams with IAV GmbH to Develop Electric and Hybrid Vehicle Powertrain Solutions with High-Performance, Lightweight Thermoplastics here

News-ID: 169872 • Views: …

More Releases from SABIC Innovative Plastics

SABIC Launches Portfolio of Antimicrobial Compounds at MD&M West to Help Custome …

According to a 2011 report by the World Health Organization, in 2002 in the United States alone approximately 99,000 deaths were linked to healthcare associated infections (HCAIs).1 Here at MD&M West (booth #1701), SABIC’s Innovative Plastics business today introduced powerful new tools to help medical device manufacturers reduce HCAIs among patients and clinicians. SABIC’s nine new antimicrobial compounds featuring silver technology have been tested for log reduction values – the…

SABIC’s 3D-Formed LEXAN™ Sheet Increases Visibility, Safety, Comfort and Per …

Operators of logging equipment require exceptional visibility and protection against debris or large objects that may enter their cabin and cause serious injury in forest environments, such as tree limbs and other machinery parts. So when Rottne Industry AB needed a high-performance glazing material for the windshields and windows of its harvesters and forwarders, it turned to

SABIC’s Innovative Plastics business for support. Working with SABIC and its distributer, Vink…

Mitsubishi Motors Corporation Selects SABIC NORYL GTX™ Resin for 2013 Outlande …

SABIC’s Innovative Plastics business today announced that Mitsubishi Motors Corporation (MMC) has chosen SABIC’s next-generation NORYL GTX™ 989 resin for the front fenders of its 2013 Outlander Sport crossover. The vehicle’s fenders are the first to be produced using 2-cavity injection molding with NORYL GTX resin, allowing MMC to cut cycle times in half and reduce tooling costs. Other major benefits of the SABIC material include weight savings vs. steel…

SABIC Makes a Splash at Fakuma with New NORYL™ Resin, Meeting Tightening Globa …

Here at the Fakuma trade fair, booth #B5-5506, SABIC’s Innovative Plastics business today announced a new NORYL™ resin that not only complies with current European and global sustainability regulations governing materials used in potable water systems, but also with new, tougher regulations slated to go into effect in 2016. Developed at SABIC’s Fluid Engineering Center of Excellence in the Netherlands, NORYL FE1630PW resin is a 30-percent glass-reinforced polyphenylene ether (PPE)…

More Releases for IAV

Automotive Engineering Service Market Size And Forecast | Top Key Players - FEV …

Global Automotive Engineering Service Market report emphasizes the detailed understanding of some decisive factors such as size, share, sales, forecast trends, supply, production, demands, industry, and CAGR in order to provide a comprehensive outlook of the global market. Additionally, the report also highlights the challenges impeding market growth and expansion strategies employed by leading companies in the "Automotive Engineering Service Market".

Global Automotive Engineering Service Market research report analyzes top players…

Global Powertrain Market (Covid-19) Impact Analysis 2020 | AKKA Technologies, IA …

Global Powertrain Market 2020 presents the accurate and tactical analysis of the market assets, growing factors, supply, industry size, regional segmentation, dynamics as well as prices variant for its projection year 2025. The report analysts have recorded data from various end-user industries and their applications across product types using a bottom-up approach. The report provides a detailed analysis of market growth, development trends, regional outlook, and a key player in…

The Structure Tester Market Economic Forecasting By 2026 | IAV, Illinois Tool Wo …

The Structure Tester Market report includes overview, which interprets value chain structure, industrial environment, regional analysis, applications, market size, and forecast. The report provides an overall analysis of the market based on types, applications, regions, and for the forecast period from 2020 to 2026. It also offers investment opportunities and probable threats in the market based on an intelligent analysis.

This report focuses on the Global Structure Tester Market trends, future…

Survey: Powertrain Testing Revenue Market Size 2018-2025 Intertek, IAV, MAE, A&D …

Powertrain Testing Revenue Market Research 2018

Globe Info Research Recently added detailed market study on the "Global Powertrain Testing Revenue Market" Research Report 2018-2025 which provides an outlook of current market value of Powertrain Testing Revenue Market as well as the expected forecast of Rate on Investment (ROI) with growing CAGR of XX% in Powertrain Testing Revenue Market by the end of 2025. The report on the global Powertrain Testing Revenue…

Powertrain Global Market 2017: Key Players – AKKA Technologies, Ricardo, FEV, …

Powertrain Market 2017

Wiseguyreports.Com adds “Powertrain Market –Market Demand, Growth, Opportunities, Analysis of Top Key Players and Forecast to 2022” To Its Research Database.

Report Details:

This report provides in depth study of “Powertrain Market” using SWOT analysis i.e. Strength, Weakness, Opportunities and Threat to the organization. The Powertrain Market report also provides an in-depth survey of key players in the market which is based on the various objectives of an organization such…

Global Powertrain Market - ThyssenKrupp, Horiba, Applus+ IDIADA, Intertek, IAV, …

Apex Research, recently published a detailed market research study focused on the "Powertrain Market" across the global, regional and country level. The report provides 360° analysis of "Powertrain Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Powertrain industry, and estimates the future trend of Powertrain market on the basis of this…