Press release

Windform NACA duct helped break land speed record

An interesting mix of homemade and high-tech: Victory Motorsports team broke the record at Bonneville Salt Flats with a 3D printed NACA duct.The Bonneville Salt Flats is a unique racing venue on the vast expanse of salt east of the town of Wendover, Utah. For more than 100 years, Bonneville has created a competitive spirit that has attracted racers from the likes of Mickey Thompson, Bobby Issac (of NASCAR fame), and Valerie Thompson (the fastest female motorcycle racer), and has challenged racers to test the limits of speed.

CRP USA is among the key players that are involved in futuristic technology in the Motorsport sector. By means of Windform materials, 3D printing is taken to the next level. CRP USA had built via Additive Manufacturing the 3D printed Windform SP NACA duct for Victory Motorsports. The intake duct was on the top of the Victory Motorsports team’s streamliner and represented an interesting mix of homemade and high-tech engineering.

Burton Brown from Victory Motorsports, a successful racing team located in Northeast Wisconsin, broke a long-standing record at Bonneville run driving the Victory Motorsports’ streamliner with the Windform SP NACA duct on it.

This new intake duct was designed by David Woodruff from Design Dreams LLC.

Few days before they left for Bonneville, Burton and the team were struggling with the duct: the nearly 28 inches long intake duct had a complex shape, and there was no time to attempt a traditional mold. Burton asked if Stewart Davis from CRP USA could help them with that challenge.

Being familiar with motorsport racing NACA ducts, the CRP USA team knew the work involved to make the surfaces smooth, required for optimum flow. Stewart Davis reviewed the part and accepted to build it using Laser Sintering technology and Windform SP material. It has been chosen for its mechanical features, excellent thermal properties, resistance to high temperatures, vibration and stability to ultraviolet radiation.

Stewart Davis stated, “This NACA duct design is unusual as it has an exterior raised around the perimeter of the duct and internal “bump.” At high speeds the raised exterior ring “pulls” air into the duct. At the base of the inlet to the turbo charger there is a round sphere like “bump” that helps direct the air flow and reduce turbulence.

We had to build it in 3 sections, but our finishing team was able to apply their knowledge and skill to give an expert polish.”

CRP USA manufactured the part in a couple of days. Burton Brown stated, “CRP USA produced an absolutely perfect piece. It gave us no issues withstanding the speed and the rough track and vibrations. It is a very light, strong material that can also take the extreme heat generated in the very tightly-fitted engine cover and body. A few years ago, I wouldn’t have dreamed of having something like this on the Streamliner.”

Based in Mooresville, North Carolina, CRP USA is partnered with CRP group.

CRP USA resides in the heart of the southern industrial and manufacturing hub, and is surrounded by growing aerospace and motorsports communities.

CRP USA manufacturers on-car and wind tunnel components for racing teams and has taken this expertise to new heights to produce parts for the space, entertainment and automotive sectors using Windform® materials and Additive Manufacturing.

CRP USA LLC

127 Goodwin Circle

Mooresville NC

28115

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Windform NACA duct helped break land speed record here

News-ID: 959983 • Views: …

More Releases from CRP USA LLC

3D printing in Space: Laser sintering process and composite material helped Port …

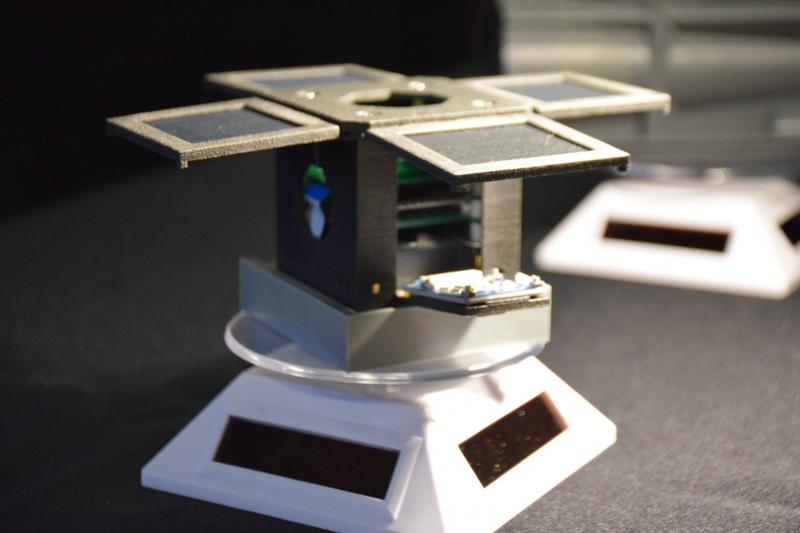

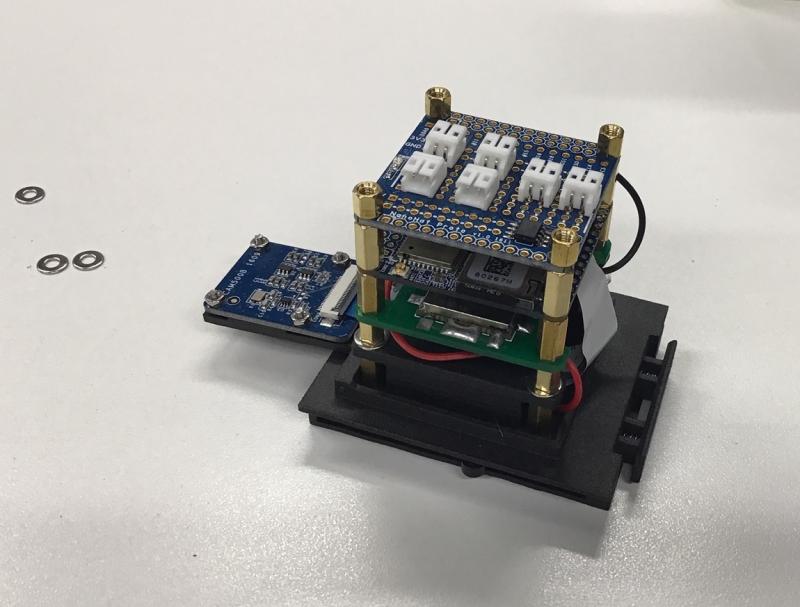

Kilogram-class satellites, like CubeSats, now have functionality that were only available in larger 100 to 1,000 kg class satellites. Recently, 3D printing has helped speed up this revolution, especially in universities.

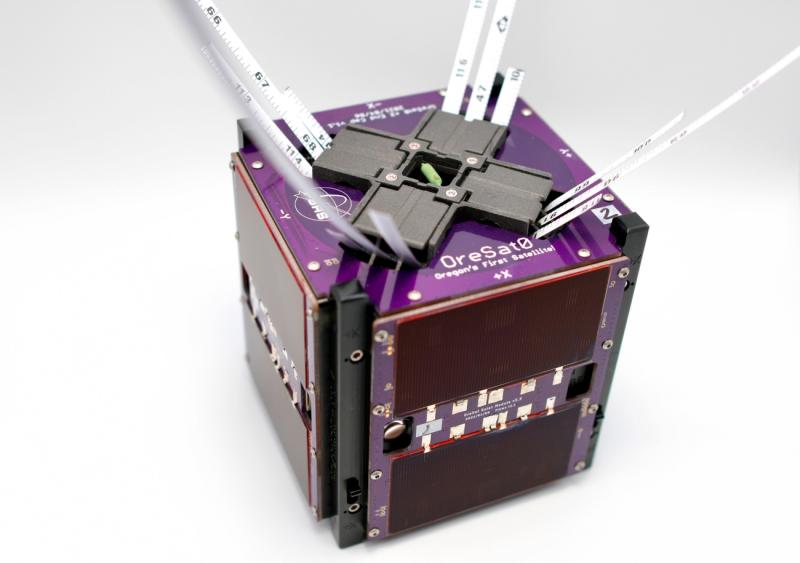

CubeSats have been launched by dozens of countries, universities and companies all around the world. And the state of Oregon joined them recently thanks to the Portland State Aerospace Society (PSAS) that built OreSat0, their very own artisanally hand-crafted…

How professional 3D printing and Carbon fiber filled composites help Formula SAE …

The CRP USA and UVic Formula Racing partnership have created across the years many functional parts in Carbon fiber filled composite materials and Laser Sintering as manufacturing process. These components distinguish for versatility, mechanical properties and durability

The versatility and mechanical properties of the functional components made in Windform materials are well recognized by specialists and insiders. One of the latest examples comes from the world of Formula SAE.

Luke Wooldridge,…

CRP USA is AS9100 certified

CRP USA, pioneering company in the fields of Additive Manufacturing and high performance composite materials, announced it has recently achieved AS9100 Rev. D certification for the manufacture of 3D printed aerospace products from its customer's component design data.

AS9100 Rev. D certification signifies CRP USA’s ongoing commitment to meeting and exceeding increasingly stringent industry requirements for aerospace related products.

"We have taken our expertise in Additive Manufacturing solutions to new heights to…

Successful use of Carbon-composite Windform® XT 2.0 and Laser Sintering in the …

US-based CRP USA manufactured three engineering models for Mini-Cubes. It is the first time that entire PocketQube functional prototypes flight-ready are manufactured using a Carbon-reinforced composite material - Windform® XT 2.0 - and Laser Sintering process

Recently Joseph Latrell, CEO of Mini-Cubes, LLC and his team started a project based on the engineering of a new 1P PocketQube flight-ready, named Discovery. The aim of the project is the creation of a…

More Releases for Motorsport

CRP Technology speaker at Composites in Motorsport

CRP Technology will be attending Composites in Motorsport as speaker.

The upcoming edition will be held 22nd - 23rd October, at the Williams F1 Conference Centre, Oxford.

CRP Technology AM expert representative will be giving a presentation entitled: “How Additive Manufacturing composite materials drive EV Motorsports”.

The speech is set at 13:30 on 23rd October 2019.

“We have been invited to submit a presentation under their electric motorsport technology session”, Franco…

Global Motorsport Market 2018 - Ferrari, McLaren, Mercedes-Benz

Apex Market Research, recently published a detailed market research study focused on the "Motorsport Market" across the global, regional and country level. The report provides 360° analysis of "Motorsport Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Motorsport industry, and estimates the future trend of Motorsport market on the basis of…

Motorsport Global Market Development 2017-2021

"Global Motorsport Market 2017-2021" The Report covers current Industries Trends, Worldwide Analysis, Global Forecast, Review, Share, Size, Growth, Effect.

. .

Description-

' …

Starworks Motorsport Bosch Engineering 250 Recap

Starworks Motorsport came into the race weekend at the scenic Virginia International Raceway (VIR) with strong momentum following their last outing where both team entries would finish with Top-10 results including a podium finish for the #8 squad. The team had always run well at VIR and was expecting similar results, but Mother Nature had other ideas.

Strong rains pounded the area during the days leading up to the race, limiting…

New motorsport magazine goes on sale

Following the recent rebranding of the popular and influential motorsport website "adrivo.com" to "Motorsport-Magazin.com", operator adrivo Sportpresse GmbH have come up with a fresh surprise as the racing season gets underway.

The 30-strong editorial team led by Stephan Heublein and Falko Schoklitsch is now to publish a new, monthly German "Motorsport-Magazin" in print format. This will be distributed via Mountains Publishing with adrivo Sportpresse GmbH having full responsibility for the…

adrivo.com becomes Motorsport-Magazin.com

Germany’s popular dedicated motorsports magazine ‘adrivo.com’ is gearing up for the new Formula One season. Sporting a new logo and fresh livery, the magazine will now be published under its new name: Motorsport-Magazin.com.

According to the latest survey by AGOF (Study Group Online Research) ‘internet facts 2008-III’, the magazine achieves a net reach of 120,000 persons per month, and that’s just in Germany. In total, Google Analytics measures ~ 1 million…