Press release

interpack: Starlinger presents trendsetting woven packaging made of PP and rPET

The bottom and, if desired, the top of IC*STAR sacks are sealed by means of hot air using a closure strip.

“The big advantage of IC*STAR sacks is that, unlike sewn sacks, they are sealed completely tight with the welded closure strip,” explains Hermann Adrigan, sales director for Starlinger. “The IC*STAR construction also practically eliminates the seam allowances required for sewn sacks, and greater strength in the sack bottom enables the use of lighter fabric. Both factors add up to cost savings in raw material – in this case polypropylene – and a reduction of the carbon footprint. Our customers are sensitive to these arguments.” The new process lends itself to production of coated or uncoated IC*STAR sacks, as well as sacks with gussets. Oil-free production makes them ideal for packaging food products such as rice, coffee, salt, sugar or flour in bulk quantities. Since the official market launch last October at the K exhibition in Duesseldorf, the first IC*STAR conversion lines have already been delivered and installed.

From bottle to sack – woven packaging for consumer goods from rPET flakes

Another focus of the Starlinger exhibit will be woven packaging from rPET flakes. This new technology developed by Starlinger is meeting with lively interest in the packaging sector: it uses material from used PET packaging such as bottles to produce tapes for weaving and, from these, big bags and sacks. Especially in consumer goods packaging, many stakeholders already place high priority on sustainability. “Sacks made from PET are noted for their specific characteristics such as stiffness, effective grease barrier and aroma protection. These make them the ideal packaging for all kinds of consumer goods,” comments Stéphane Soudais, general manager of Starlinger’s Consumer Bags Division. “PET is also one of the few types of plastic which enable closed loop production. With our technology we can make PET bottle flakes directly into woven tape fabric, which is then used in production of container bags or consumer goods packaging like the PP*STAR pinch bottom sack laminated with BOPET film. The rPET sacks are recyclable after use and can be used in the production of new sacks or for other applications.”

Note: PP*STAR® and IC*STAR® are registered trademarks. PP*STAR® and IC*STAR® sacks are produced exclusively on Starlinger machines.

Starlinger at interpack, Duesseldorf/Germany, May 4 - 10, 2017,

Hall 11/Stand C 20

About Starlinger & Co. Ges.m.b.H.:

Starlinger is a Vienna-based engineering company with production sites in Weissenbach and St. Martin, Austria, as well as Taicang, China. As the world’s leading supplier of machinery and complete lines for woven plastic bag production, recycling and PET extrusion and refinement, Starlinger & Co. Ges.m.b.H. is a synonym for leadership in quality and technology in over 130 countries. Founded in 1835, the family-owned business has been exporting machines worldwide for more than 45 years with an export quota of over 99.5 %.

Branches in Brazil, China, India, Indonesia, Russia, South Africa, USA and Uzbekistan ensure quick and professional technical support and service.

Starlinger & Co. Ges.m.b.H.

Sonnenuhrgasse 4,

1060 Vienna

Austria

Press Contact: Ms. Sigrid Eder

T: +43 1 59955-1251

F: +43 1 59955-180

E: sales.ed@starlinger.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release interpack: Starlinger presents trendsetting woven packaging made of PP and rPET here

News-ID: 483105 • Views: …

More Releases from Starlinger & Co. Ges.m.b.H.

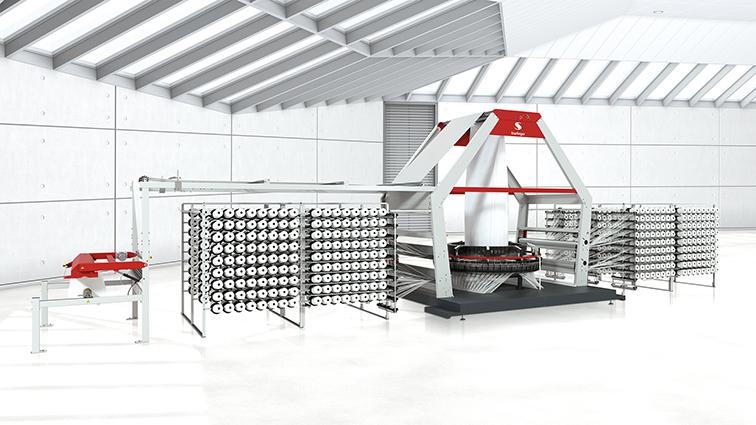

Starlinger provides circular loom to Bangladesh University of Textiles

Modern teaching methods combine theory and practice. Austrian world market leader Starlinger recently provided the Bangladesh University of Textiles with a circular loom RX 6.0 for training purposes.

In mid-2017, the Bangladesh University of Textiles was looking for a state-of-the-art circular loom that could be used in the training of its students. Given Starlinger’s leading position in the field, the university approached the Austrian engineering company with the request for an…

Time to freshen up: Starlinger odor reduction at NPE 2018

A circular economy in plastic packaging is currently on everyone’s agenda. Clearly, the recycling of packaging saves raw material and reduces waste as well as CO2 emissions. At NPE, Starlinger will present two technologies that help advance closed loop packaging.

Recycling is key in achieving a circular economy. But in order to be fit for reuse in production, recycled material needs to match the quality of virgin resin. The removal of…

Outstanding PET bottle-to-bottle recycling results on Starlinger line with Nords …

The Starlinger recoSTAR PET bottle-to-bottle recycling line which has been installed in April 2016 in the plastics recycling facility of Canadian water bottler Ice River Springs in Feversham, Ontario, is delivering excellent production results. Due to Nordson’s BKG® Flex Disc filter cartridge, which has been included for melt filtration, the production output is even higher than the values guaranteed in the acceptance protocol. Also the purge rate has been…

Starlinger: Lowest production cost per square meter with new 8-shuttle circular …

Starlinger’s FX 8.0 circular loom for the production of heavy-duty tape fabric ranks among the leading models on the market: with 850 picks per minute it is more than 30 % faster than comparable circular looms, and it has the lowest production cost per square meter of fabric.

Being the latest development in the FX loom series from Starlinger, the FX 8.0 operates with eight weaving shuttles and features a…

More Releases for IC*STAR

Battery Management IC Market: Information by Type (Battery Charger IC, Fuel Gaug …

Battery management ICs are integrated circuits, used in an electronic system to manage rechargeable batteries. These are small electronic components that include transistors, diode, among others, on a semiconductor crystal or chip. Battery management IC protects the battery from operating outside from its SOA (Safe Operating Area) and monitors the state of the battery, authenticates the battery, calculate and report data, among others. This battery management ICs are of different…

3D IC & 2.5D IC Packaging Market Size, Share & Forecast 2025

2.5D interposer is also a 3D WLP that interconnects die side-side on a silicon, glass or organic interposer using TSVs and RDL. In all types of 3D Packaging, chips in the package communicate using off-chip signaling, much as if they were mounted in separate packages on a normal circuit board.

3D ICs can be divided into 3D Stacked ICs (3D SIC), which refers to stacking IC chips using TSV interconnects, and…

3D IC and 2.5D IC Market Opportunities, Challenges, Strategies & Forecasts 2019- …

The 3D IC and 2.5D IC market report [6 Year Forecast 2019-2025] focuses on Major Leading Industry Players, providing info like company profiles, product type, application and regions, production capacity, ex-factory price, gross margin, revenue, market share and speak to info. Upstream raw materials and instrumentation and downstream demand analysis is additionally administrated. The 3D IC and 2.5D IC market business development trends and selling channels square measure analyzed. From…

Digital Power Management Multichannel IC Market by Product Type (Battery Managem …

Digital power management multichannel IC technology is rapidly adopted in semiconductor and electronics sectors. In addition, scalable and distributed power management of this technology is estimated to fuel the market growth in both non-industrial and industrial sectors.

Global digital power management multichannel IC market is expected to reach $35,109 million by 2022 from $11,861 million in 2015, and growing at a CAGR of 16.3% from 2016-2022. Digital power management multichannel IC…

Global 3D IC & 2.5D IC Packaging Industry Research by Company, Type & Applicatio …

ReportsnReports recently announces a latest research report titled “Global 3D IC & 2.5D IC Packaging Market 2018” which highlights the 3D IC & 2.5D IC Packaging Market size, comprehensive 3D IC & 2.5D IC Packaging Industry dynamics and high-tech updates of global 3D IC & 2.5D IC Packaging Market with respect to 3D IC & 2.5D IC Packaging Industry opportunities, threats, challenges, constraints, cost structure and current trends in the…

Global 3D IC and 2.5D IC Packaging Market Analysis And Forecast Report 2017

"The Report Global 3D IC and 2.5D IC Packaging Market Research Report 2017 provides information on pricing, market analysis, shares, forecast, and company profiles for key industry participants. - MarketResearchReports.biz"

In this report, the global 3D IC and 2.5D IC Packaging market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016…