Press release

Why precision machining services are so important

"Precision Machining: Crafting the Foundation of Modern Innovation with Unmatched Accuracy and Reliability."The Role of Precision Machining in Modern Manufacturing Efficiency

The best precision machining services factory - TIKPRECISION(https://www.tikprecision.com/)

Why Precision Machining Services Are So Important

In the realm of modern manufacturing, the significance of precision machining services(https://www.tikprecision.com/) cannot be overstated. These services are the backbone of numerous industries, ensuring that components and parts are produced with the highest level of accuracy and quality. Precision machining plays a pivotal role in manufacturing efficiency, and its importance is reflected in the performance and reliability of the final products.

At the heart of precision machining is the ability to produce parts that meet exact specifications. This level of accuracy is crucial for components that are destined for critical applications, such as in the aerospace, medical, and automotive industries. In these sectors, even the slightest deviation from the required dimensions can lead to catastrophic failures. Therefore, precision machining services provide the assurance that each part will fit and function as intended, which is essential for the safety and functionality of the end products.

Moreover, the efficiency of modern manufacturing processes is heavily reliant on the repeatability that precision machining offers. Once the specifications for a part are set, precision machines can replicate the part with minimal variation, time and time again. This consistency is vital for mass production, where thousands or even millions of identical parts may be needed. By guaranteeing uniformity, precision machining services enable manufacturers to maintain a continuous flow of production without the need for frequent adjustments or downtime to correct errors.

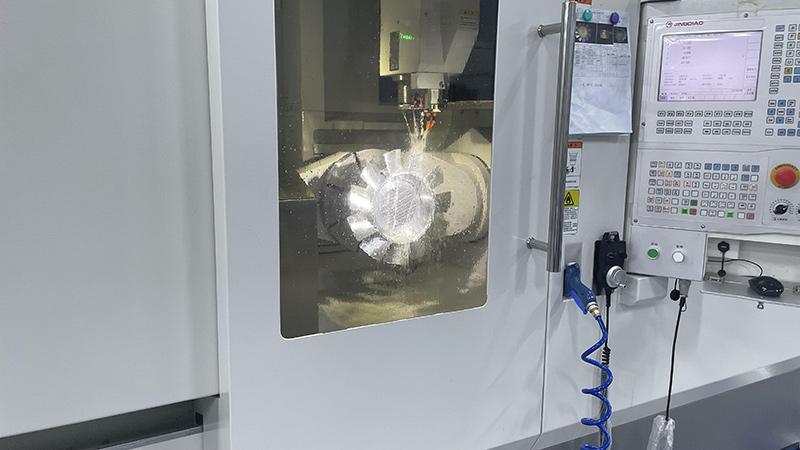

Another aspect where precision machining services prove their importance is in the realm of material utilization. Advanced machining techniques allow for the material to be used more efficiently, reducing waste and lowering production costs. High-speed CNC (Computer Numerical Control) machines can carve out complex shapes with minimal excess material, which not only saves on raw materials but also minimizes the energy required for production. This efficient use of resources is not only economically beneficial but also aligns with the growing emphasis on sustainable manufacturing practices.

Furthermore, the evolution of precision machining has kept pace with the increasing complexity of designs. As products become more sophisticated, the need for intricate parts with tight tolerances grows. Precision machining services have

Ensuring Product Quality and Consistency Through Precision Machining (https://www.tikprecision.com/)

Why precision machining services are so important

In the realm of manufacturing, the importance of precision machining services cannot be overstated. These services are the backbone of producing parts and components with the utmost accuracy and consistency, which is paramount in ensuring product quality. Precision machining involves the removal of material from a workpiece while holding close tolerances to create a finished product that meets exact specifications. This process is critical in a wide range of industries, including aerospace, automotive, medical, and electronics, where even the slightest deviation can lead to product failure or safety hazards.

The significance of precision machining services lies in their ability to produce complex parts with incredible precision. Advanced machines, such as CNC (Computer Numerical Control) equipment, are capable of performing multiple operations with high precision and minimal human intervention. This automation not only increases efficiency but also reduces the likelihood of human error, ensuring that each part is manufactured to the same exacting standards. As a result, businesses can rely on the consistency of the parts produced, which is essential for maintaining the integrity of the final product.

Moreover, precision machining services (https://www.tikprecision.com/) play a crucial role in material utilization and waste reduction. By precisely cutting materials to the required dimensions, there is minimal excess, which not only conserves valuable resources but also reduces costs associated with material wastage. This efficiency is not only beneficial from a financial standpoint but also supports sustainable manufacturing practices, which are increasingly important in today's environmentally conscious market.

Another aspect where precision machining services prove their worth is in the realm of innovation. The ability to produce intricate and complex parts allows for the development of new products and technologies. Designers and engineers can push the boundaries of what is possible, knowing that there are machining services capable of turning their most intricate designs into reality. This fosters a culture of innovation that drives industries forward, leading to advancements that can improve our daily lives and open up new markets.

Furthermore, the reliability of precision machining services is a cornerstone for building trust with customers. When businesses can consistently deliver high

The Impact of Precision Machining on Aerospace and Medical Industries

Why Precision Machining Services Are So Important

In the realm of modern manufacturing, precision machining services stand as a cornerstone, underpinning the success of critical industries such as aerospace and medical. These services, which involve the removal of material from a workpiece while holding close tolerances, are not just important; they are indispensable for the creation of intricate parts that must meet the highest standards of accuracy and reliability.

The aerospace industry, with its stringent demands for safety and performance, relies heavily on precision machining. Aircraft components are subject to extreme conditions and must withstand forces like intense pressure and temperature fluctuations without fail. Consequently, there is no margin for error in their manufacturing. Precision machining ensures that each part - whether it be a turbine blade or a fuselage panel - adheres to exact specifications. This level of accuracy is crucial not only for the functionality of the aircraft but also for the safety of passengers and crew. Moreover, the ability to produce lightweight and strong materials through advanced machining techniques contributes significantly to the efficiency and sustainability of aircraft, as it directly impacts fuel consumption and emissions.

Similarly, the medical industry benefits from the high standards set by precision machining services. Medical devices and implants, such as pacemakers, joint replacements, and surgical instruments, require the utmost precision to function effectively and safely within the human body. The tolerances here are often even tighter than in aerospace, as the difference of a few micrometers can determine the success of a medical procedure or the compatibility of an implant. Precision machining enables the production of complex geometries and smooth finishes that are essential for medical applications, where any imperfection can lead to serious complications or the body's rejection of a medical device.

Furthermore, the evolution of precision machining has kept pace with the rapid advancements in both aerospace and medical technology. As these industries innovate, they demand components that are not only more precise but also made from advanced materials that can be difficult to machine. Precision machining services have risen to this challenge, employing state-of-the-art equipment

Advancements in Precision Machining Technologies and Their Importance

Why Precision Machining Services Are So Important

In the realm of manufacturing, precision machining services stand as a cornerstone, underpinning the success of countless industries. These services, which entail the shaping of materials into desired dimensions and geometries with meticulous accuracy, are not just a component of the production process; they are a critical factor in the advancement of technology and the delivery of high-quality products.

The importance of precision machining is magnified when one considers the demands of modern applications. From aerospace to medical devices, the tolerances - the degree to which a manufactured part must adhere to its specified dimensions - are becoming increasingly stringent. This is where precision machining shines, as it allows for the creation of components with tolerances that are often measured in micrometers, ensuring that parts fit together perfectly and function as intended.

Moreover, the evolution of precision machining technologies has been nothing short of revolutionary. The advent of computer numerical control (CNC) machines has transformed the landscape of manufacturing. CNC machining (https://www.tikprecision.com/) provides unparalleled consistency and repeatability, which is paramount in mass production where every part must be identical to the last. This level of consistency is not just beneficial for efficiency; it is also crucial for safety, especially in industries like automotive and aerospace, where a single faulty component can have catastrophic consequences.

Furthermore, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) with CNC machines has streamlined the production process. Designers and engineers can now translate complex geometries from digital blueprints directly into physical parts with a level of precision that was once unattainable. This seamless transition from design to production not only accelerates the manufacturing cycle but also minimizes the potential for human error, ensuring that the final product adheres closely to its original specifications.

The significance of precision machining also extends to the realm of innovation. As new materials and composites are developed, the ability to machine these materials with high precision enables their use in cutting-edge applications. For instance, the

Room 1508, 15/F., Office Tower Two, Grand Plaza, 625 Nathan Road

Tik precision Manufacturing Co., Ltd. was established in 2018 with a plant area of 8,000 square meters. With more than 50 sets of well-equipped domestic and foreign advanced CNC equipment, we established a strict production and quality management system, and has a team of skilled technicians. Combined with industry-leading equipment and technology, comprehensive professional knowledge, good coordination and communication ability, we are able to grasp the customer's product design, development and production requirements in depth and accurately.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Why precision machining services are so important here

News-ID: 3478184 • Views: …

More Releases from Tik Precision Manufacturing Co.,Limited

Some new technologies in the field of CNC machining services

"Precision Redefined: Elevating Craftsmanship with Cutting-Edge CNC Innovations"

Advances in High-Precision CNC Machining Technologies

The landscape of CNC (Computer Numerical Control) machining services is continually evolving, with new technologies emerging that push the boundaries of precision, efficiency, and capability. These advances are revolutionizing the way manufacturers operate, offering unprecedented levels of accuracy and opening up possibilities for the production of complex parts that were once considered unattainable.

One of the most significant developments…

More Releases for Machining

Opportunities for the Global On Site Machining (In-Place Machining, In-Situ Mach …

Worldwide Market Reports published a report titled "On Site Machining (In-Place Machining, In-Situ Machining) Market" research report which covers comprehensive data on prevalent trends, drivers, growth opportunities, and restraints that can change the market dynamics of the global industry. This report provides an in-depth analysis of the market segmentation that includes products, applications, and geographical analysis. Global On Site Machining (In-Place Machining, In-Situ Machining) market report delivers a close watch…

On Site Machining (In-Place Machining, In-Situ Machining) Market to Witness Huge …

According to Market Study Report, On Site Machining (In-Place Machining, In-Situ Machining) Market provides a comprehensive analysis of the On Site Machining (In-Place Machining, In-Situ Machining) Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Download FREE Sample Report @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5544564

The report provides a comprehensive analysis of…

CNC Machining by GD Rectifiers

CNC Machining, also known as Computer Numerical Control machining is a cost effective way to increase efficiency in the workplace. In recent years, CNC machining has become an extremely popular manufacturing asset, for its intricate and complex capabilities designed for aerospace, marine, automotive and medical industries.

GD Rectifiers operates a fast and versatile CNC machine shop, offering customers the shortest lead times, competitive pricing and single source benefits. GD Rectifiers uses…

Air Bearing Spindle Market Drivers, Restraints, Opportunities, and Threats 2018 …

Global Air Bearing Spindle Market: Introduction

Air bearing spindle is a motor-driven shaft that either position and transmits power to a cutting tool or holds a workpiece. Air bearing spindles have the advantages of very low error motions due to fluid-film-averaging effect, frictionless & high-performance positioning, cleanliness, and minimal maintenance. Thus, air bearing spindle is equipped with air bearings which allow the spindle to rotate at higher speeds.

For applications, such as…

Rapid Machining Launches New Service

Rapid Machining, one of the largest prototype machining manufacturers in the United States, is excited to announce a new standard 5 day lead time service for lathe parts. Responding to customer demand, Rapid Machining purchased new equipment and reconfigured the manufacturing floor to make this lead-time reduction possible from a standard 7 day lead time. The new service is currently available for lathe parts with a variety of materials and…

Rapid Machining Receives ITAR Registration

Demonstrates Commitment to Military, Defense, and Government Markets

Nashua, NH, April 13, 2011: Rapid Machining, specializing in rapid turnaround of quick turn machined prototypes, announced today that they have received their official International Traffic in Arms Regulations (ITAR) registration from the US Department of State, Bureau of Political-Military Affairs. This registration documents Rapid Machining's dedication to adhering to the regulations that control the export and import of defense-related articles…