Press release

Guyson Blast Cabinet Etches Busbars

Guyson International, the UK’s foremost industrial finishing equipment manufacturer, has recently installed a specially configured Guyson Euroblast® 7PF (Pressure Fed) blast cabinet into one of the world’s leading designers and manufacturers of switchgear and instrumentation. The cabinet is to provide a blast etched surface, on their range of high voltage busbars, to improve adhesion of a special non-conductive coating.The company’s existing blast cabinet system had suffered from several operational problems, so the search was on for an improved solution with better blast media handling and operator efficiency. With three tenders in place, the operators and Maintenance Manager visited Guyson’s ‘Component Finishing Centre’ at Skipton to try out Guyson’s proposed manual blast system on their components. “All of the operators bought into the Guyson blast unit straight away and it was their unanimous preferred option” said their Maintenance Manager.

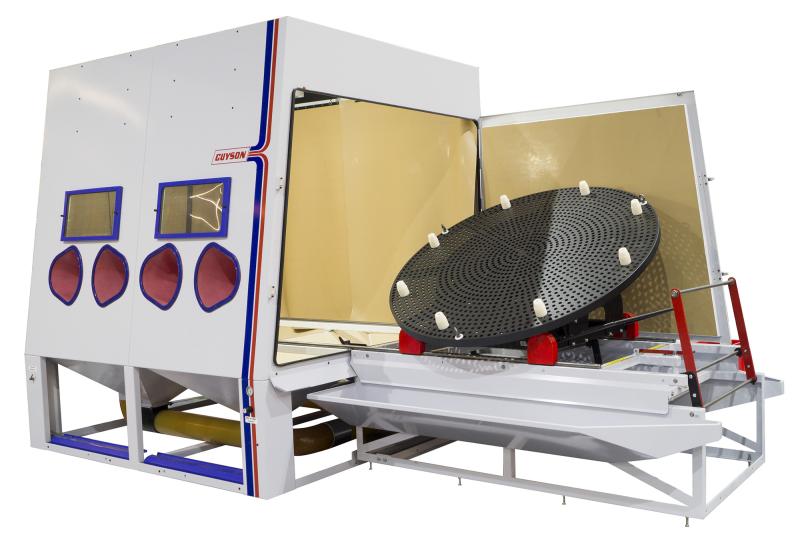

The chosen Euroblast 7PF blast cabinet is from Guyson’s premier industrial quality range and delivers exceptional component access, with doors opening to the front, top and side, and so facilitates easy loading of components. In fact, with the blast chamber being oblong rather than square in shape, it proves a popular choice amongst customers for blasting longer components. But due to the length of some of their copper, silver and tin electro-plated busbars being even longer than the width of the Euroblast 7PF cabinet; a special cabinet design was needed.

This was drawn up, in 3D CAD, by Guyson’s in-house design team and incorporated a 700 mm extension box on the left hand side of the cabinet, supported by legs, and a cut out profile in the right hand door (with blanking door to prevent media escape) so that longer busbars can be fed into the cabinet for selective blast etching. The remainder of the pressure fed blast system includes a Guyson’s G27 pressure pot, C800 twin cartridge dust collector and a ‘High Efficiency’ cyclone. This latter item is designed to remove the majority of dust and fines from reaching the dust collection unit, thus extending the life of the filter cartridges between changes.

Guyson Euroblast PF systems are designed for speed, giving faster cleaning times (up to four times faster than suction fed or venturi systems) to meet higher production requirements and at peak demand this blast system can be working for the entire length of a full shift so it is necessary that the blast system quickly produces a perfectly keyed surface for the powdered coating to adhere to in the oven.

Whatever your blast cabinet requirement Guyson will have the answer. Contact Guyson’s Customer Service Department now to arrange free blast trials on your components, prove the process and make recommendations on the most suitable cabinet for you – call 01756 799911 or email info@guyson.co.uk

Guyson International Limited

Snaygill Industrial Estate, Keighley Road,

SKIPTON, North Yorkshire, England BD23 2QR

About Guyson

Guyson International Limited is a privately owned family company with a world-wide reputation for excellence in the design and manufacture of blast finishing, spray wash and ultrasonic cleaning equipment. Formed over 80 years ago, the company is registered to ISO 9001: 2015 and 18001:2007, and its head office is located at Skipton, North Yorkshire, in the north of England. Guyson has four international subsidiary companies: Guyson Corporation of the USA, located in Saratoga Springs, New York State; Guyson SA, situated near Paris, France; Guyson Sdn Bhd in Penang, Malaysia; and Guyson CN, in Wuxi, Jiangsu Province, China.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Guyson Blast Cabinet Etches Busbars here

News-ID: 1878662 • Views: …

More Releases from Guyson International Ltd

Extra-Large Blast Machine for Blast Etching Aerospace Rings

Guyson International, the UK's foremost industrial finishing equipment manufacturer, has installed a Guyson Euroblast® 2-metre PF (Pressure Fed) blast system into a division of a leading European aerospace company. The extra-large blast cabinet is used to deliver a uniform etched key surface on a range of machined circular aluminium rings prior to bonding.

After blast trails performed at the company's Skipton demonstration centre, a Euroblast 2-metre PF blast system (2.1…

Guyson Twin Spindle Blast Machine for Etching Tubular Components

Guyson International, the UK's leading manufacturer of industrial finishing equipment, has recently manufactured and installed into a UK manufacturing company an automated Multiblast RSB twin spindle blast system for externally blast etching various sizes of tubular components. This new blast system incorporates two rotating blast stations with matching top clamps, to hold the product securely, whilst two vertically traversing blast guns produce a uniform blast etch finish over the length…

Guyson Staff Clock-Up 180 Years!

At Guyson International's Skipton headquarters, Monday 15th August saw rain, much needed, and celebrations, much deserved. Employees from the company's blast and wash division gathered outside to congratulate seven employees who were awarded long service awards. And between them amassed a total of 180 years of service at Guyson, with one, Keith Miller celebrating 50 years of service.

In typical unpredictable UK weather, after so many days of bright hot sunshine,…

Guyson Equipment Cleans and Maintains Planing and Woodcutting Tools

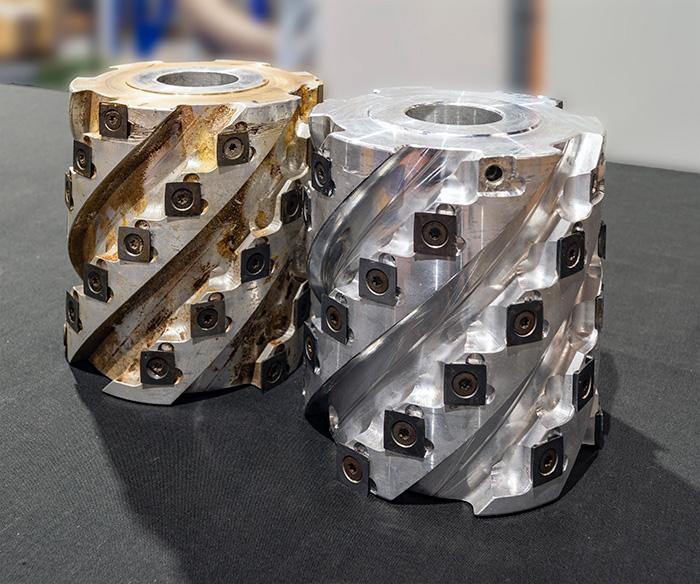

Guyson International, one of the UK's leading manufacturers of industrial finishing equipment, recently delivered a KS450 ultrasonic cleaning tank and a Formula 1200 benchtop bead blast cabinet to RHW (R H Wilson (Lakes) Ltd.) of Kirkby Stephen, a leading timber importer and supplier, for cleaning and maintaining their wood cutting and planing tools.

The problem was how best to clean 'helical planer blocks' to remove a build-up of pitch, sap, resin…

More Releases for Euroblast

Guyson Exhibits Finishing Equipment Technologies at Global Industrie

Guyson SA (Hall 6, Stand 6P18), one of the leading European finishing equipment manufacturers, will exhibit at the Global Industrie show taking place at the Paris Nord Villepinte Exhibition Center on 17-20th May 2022. There will be an opportunity to view both Guyson's blast finishing and ultrasonic cleaning equipment lines of industrial finishing equipment on the stand, which will be staffed by French and English speaking Guyson sales engineers to…

Guyson Airwash Cabinet for Cleaning Railway Braking Systems at Metro Madrid

Leading Finishing equipment manufacturer, Guyson International Limited with its Spanish distributor, Materias Primas Abrasivas, S.L. (MPA), has recently supplied and installed a Guyson Euroblast 8 Airwash cabinet, into Metro Madrid's main maintenance workshop for removing dust particles and other contaminants from the braking systems of underground trains.

The health and safety and wellbeing of Madrid Metro’s maintenance staff was the primary concern when selecting the Guyson airwash system. The Euroblast 8…

Guyson Installs Multiple Blast Cabinets into Additive Manufacturer

Guyson International has recently installed four Guyson Euroblast 8, pressure feed, blast finishing systems complete with side loading turntables, into the brand new additive manufacturing (AM) factory of Materials Solutions (A Siemens Business) to remove semi-sintered particles from their components and provide an even cosmetic finish. These larger blast finishing systems augment an existing batch of smaller model 2 and model 4 Guyson Euroblast blast cabinets and continue the customer’s…

New Guyson ‘Standard Blast Products’ Brochure

To kick off the New Year, Guyson International, the UK’s leading industrial finishing equipment manufacturer, has just issued a new ‘Standard Blast Products’ brochure that all in one place showcases its comprehensive range of ‘standard’ blast cabinets. This glossy twelve page brochure features their premium ATEX rated blast cabinets, its professional Euroblast® range, light industrial Formula cabinets and specialist alloy wheel refurbishment cabinets.

Potential customers are invited to use the…

Guyson to Launch New ATEX Blast Cabinet Systems at TCT

Industrial finishing equipment manufacturer Guyson International will be showcasing their new Euroblast® Ex range of blast systems at TCT 2018 – stand S44. Designed for use with potentially explosive powders and certified to the directive ATEX 2014/34/EU the systems are coded; ATEX II 2/3 D Ex h T135 °C Db/Dc.

Particularly relevant in Additive Manufacturing (AM) applications where the use of fine powders of materials…

Guyson Bead Blast Cabinets for Surface Finishing Additive Manufactured Parts

Industrial finishing equipment manufacturer Guyson International has recently installed two Euroblast® 4SF (suction fed) blast cabinets into the Department of Engineering at the University of Wolverhampton, for surface finishing Additive Manufactured parts and blast etching build plates.

The initial enquiry came at last year’s TCT + Personalize show, held at the NEC, which Guyson regularly attends as the leading manufacturer of bead blasting equipment for surface finishing 3D Print and…